Performance Exhaust Systems: Pipe End Forming

Depending on the specific application, each end of a pipe may be unmodified, featuring the same diameter as the rest of the pipe. Or, one or both ends may feature a smaller or larger diameter in order to provide a slip-together mating to a pipe or muffler.

Find more stories like this in the book: PERFORMANCE EXHAUST SYSTEMS

Get your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy and paste this link to share: https://www.cartechbooks.com/blogs/techtips/pipe-end-forming

The end of a pipe can be undersized, using a hydraulic reducing die, or it may be oversized using a swedging oversize die and expander mandrel. A pipe end may also be formed to feature a 90-degree flange lip where a flat mating flange is needed.

A ball-socket connection can also be obtained, where perhaps one end features a male radiused ball shape, and the mating pipe requires a female radiused end. A ball-socket mating (secured by a pair of flat bolt-together flanges) is often desired because it allows a degree of flexibility for adjusting the system for pipe angles.

Pipe bender shops maintain a selection of pipe expansion-and reduction-mandrels for a wide range of sizes.

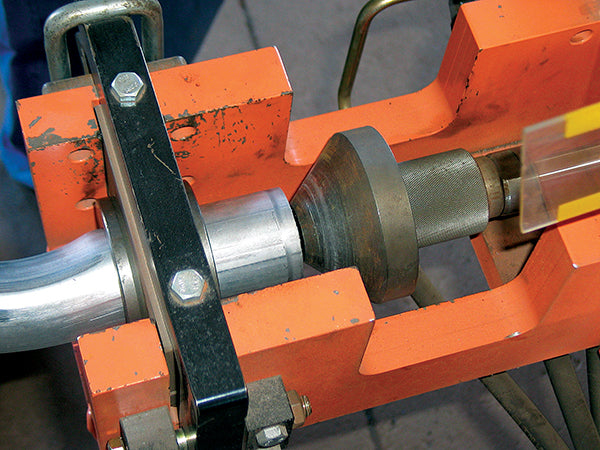

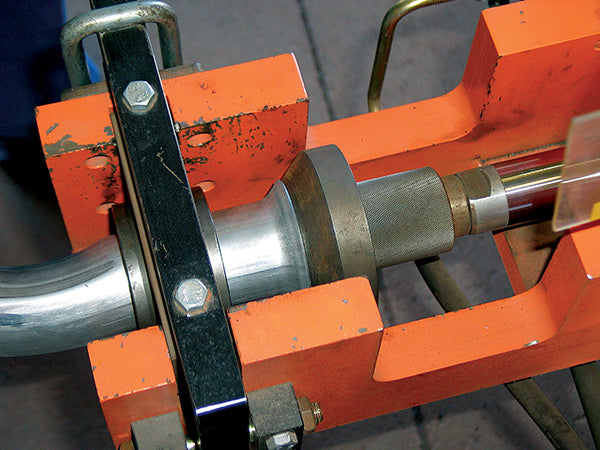

A manual or semi-automatic pipe-bending machine, depending on the model, may also feature pipe-flaring adapters. This conical male die is being used to create a female flare.

With the pipe locked in place, a hydraulic ram on the machine pushes into the pipe creating a flare. Since this isn’t a fully automated machine, the amount or depth of the flare must be visually monitored by the operator.

Find more stories like this in the book: PERFORMANCE EXHAUST SYSTEMS

Get your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy and paste this link to share: https://www.cartechbooks.com/blogs/techtips/pipe-end-forming

If a square lip is required (for use with bolt-together flanges), a flat-faced mandrel is used to continue pressing against the initial flare, resulting in a flat or “square” flare lip.

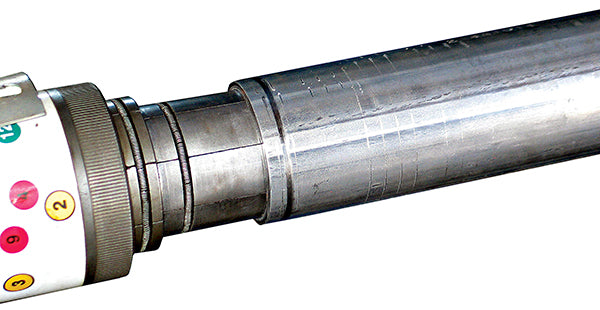

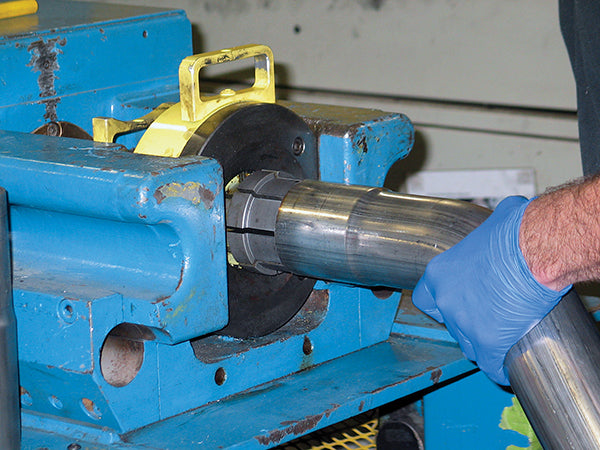

A manual hydraulic or semi-automatic bending machine may also feature a pipe expander capability. A multi-piece mandrel is selected for the desired expansion diameter and installed onto the machine’s arbor.

With the mandrel collapsed, it inserts easily into the end of the pipe.

Depending on the requirements for a specific pipe, one or both ends may need to be reduced or expanded to allow a slip-fit joint.

This pipe’s end has been reduced to a specific diameter in a reducer die.

This 3-inch pipe’s end has been expanded to allow a slip-fit to a muffler that has a 3-inch entry-pipe stub.

After expanding the tip, the technician verifies fit with a 3-inch sample piece.

Ball-socket-style connections allow slight angle adjustments for the pipes.

Find more stories like this in the book: PERFORMANCE EXHAUST SYSTEMS

Get your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy and paste this link to share: https://www.cartechbooks.com/blogs/techtips/pipe-end-forming