In its simplest terms, an internal combustion engine is nothing more than an air pump. The more air that’s drawn into a cylinder as the intake valve opens and closes, the more intense the combustion event is when the appropriate amount of fuel is added, and that translates into greater potential for horsepower and torque. A given engine can only use so much airflow. Just how much depends upon displacement, but maximum operating speed and operational efficiently are most important.

An internal combustion engine is basically an air pump. Improving its ability to move a greater volume of air almost always increases output in a particular range. Selecting a cylinder head with the proper amount of intake and exhaust airflow and volume generates the greatest amount of horsepower and torque over the intended operating range.

Find more tips like this in the book: HOW TO BUILD MAX-PERFORMANCE PONTIAC V-8 ENGINES

Learn more about super tuning Holley carbs. Get your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy and paste this link to share: https://www.cartechbooks.com/blogs/techtips/cylinder-heads-performance-guide-for-pontiac-v-8-engines

Intake Airflow

Peak intake airflow is a common reference when comparing cylinder heads. While that figure is very important, especially for attaining strong peak horse power, a cylinder head spends very little time at peak valve lift and considerably more time reaching that point. Considering airflow throughout the entire valve lift range is more important. Strong low- and mid-lift airflow starts cylinder fill quickly and effectively and continues filling the cylinder until the intake valve closes. SuperFlow Corporation is an airfl ow industry leader and it has developed a mathematical equation that can predict approximate horsepower based upon airflow at a specific test pressure. When discussing peak airflow of a cylinder head today, it’s usually stated at 28 inches of water pressure. Though Super Flow lists formulas for all common airfl ow test pressures, I am including only the one for 28 inches since it’s a pressure most are familiar with.

Horsepower per Cylinder = (Cpower x Peak Airfl ow) x Number of Cylinders

The equation arrives at peak horsepower per cylinder by multiplying peak airflow by the SuperFlow’s predetermined “Coeffi cient of Power” (Cpower). At 28 inches of pressure, Cpower is equal to. 260. You must then multiply the result by the number of cylinders for the subject engine, 8 in the instance of the Pontiac. If your cylinder heads are capable of providing 240 cfm of peak intake airfl ow at 28 inches of pressure, the engine could produce as much as 500 hp. Simply reversing the formula can determine approximately how much peak airfl ow is required to achieve a target horsepower.

Peak Intake Airflow = (Target HP ÷ Number of Cylinders) ÷ Cpower

If 600 hp is your goal, for instance, it requires an intake port capable of flowing nearly 290 cfm. SuperFlow’s equation is reasonably accurate. You may have noticed that it does not consider engine displacement. That’s because peak horsepower is derived from engine speed, and not size. A small-displacement engine can make an equal amount of horsepower as a larger engine using the same available airflow, only its horsepower peak occurs at a much higher RPM.

A flow bench is used to measure the intake and exhaust airflow of a cylinder head. A typical cast-iron Pontiac D-port measures 190 to 210 cfm of peak intake airflow at 28 inches of pressure. Most aftermarket aluminum castings flow anywhere between 260 and 330 cfm. Specialized castings can flow more than 400 cfm.

It’s easy to determine which of the ports are larger. A smaller port flows well for strong peak horsepower, but maintains good port velocity for quick throttle response and low end torque. A larger port provides much more peak airflow while delivering a greater volume of air to engines that operate at high RPM. The tradeoff is less port velocity at low speed.

Port Volume

A greater volume of airflow is required as engine speed increases. The overall size of an intake port is referred to as its cross-sectional area. It’s calculated by multiplying the recorded height and width at particular points within the port. When comparing cylinder heads where intake port length is nearly identical, port volume is a common fi gure that lends a general insight to the crosssectional area of a particular cylinder head. Generally stated in displaced volume of cubic centimeters, port volume is relative to engine size and can help determine how a particular cylinder head infl uences engine operation.

In general terms, a larger intake port flows a greater volume of air. While that can allow a given engine to operate effectively and effi ciently at higher speed, the tradeoff is less port velocity. Port velocity is a critical element of engine performance. If you imagine airflow as a liquid, and relate it to water through a hose, the same volume of water exits a garden hose with far more velocity than it would a fire hose. Applying that concept to airflow passing through the intake ports of your Pontiac’s cylinder head, it’s easy to understand its effect on cylinder fill.

A smaller intake port is ideal for an engine that spends most of its time operating from idle speed to a moderate shift point such as a typical passenger car engine or a street/strip application where a broad power band is required for operation over a wide range. A larger port is ideal for a race engine that operates in a relatively narrow RPM range, and one where low-speed street manners are not a concern. Smaller-displacement engines, particularly those with a shorter crankshaft stroke, are more sensitive to port volume. A larger engine such as the 455 simply moves more air per revolution than a smaller engine because of its size, and its longer crankshaft stroke tends to pull harder on the intake port. A larger engine can tolerate greater port volume without as many negative effects. That doesn’t suggest that a port can never be too small or too large, however.

Exhaust Airflow

The byproducts of normal combustion must be efficiently expelled out the exhaust port during the exhaust stroke. Exhaust airflow is equally as important as intake airflow. A typical exhaust port isn’t nearly as large as the intake port on a given cylinder head, and its valve isn’t quite as large, so it doesn’t have the capacity to move as much static airflow. That’s not a signifi cant issue, however.

Many builders agree that an exhaust port that flows 70 to 75 percent of the intake port throughout the entire lift range is sufficient for maximum performance. For instance, an intake port that peaks at 300 cfm might perform best with an exhaust port that peaks at 210 to 225 cfm. Just how much exhaust flow is required largely depends upon the compression ratio of a particular engine. The compressive force that occurs as the air/fuel mixture ignites pushes the piston downward, rotating the crankshaft, and ultimately motivating the vehicle. As the piston reaches bottom dead center (BDC) during the power stroke and begins traveling upward on the exhaust stroke, the exhaust valve opens and excess pressure trapped in the cylinder vents outward through the exhaust port. It’s commonly referred to as “blow down.”

A cylinder is under pressure after the combustion event. As soon as the exhaust valve opens, exhaust gas begins venting out under its own pressure. The piston pushes the residual gas out. The exhaust valve and port do not need to be quite as large as the intake. An ideal exhaust port flows between 70 and 75 percent of the intake port throughout the entire lift range. A short extension is often used when measuring exhaust airflow on a flow bench. It replicates the first few inches of the header tube and can increase flow by several percent.

A high-performance valve job consists of multiple angle seat cuts that improve the airflow’s transition from the bowl area into the chamber. Modern cutting bits can make several cuts at one time. A multiple angle “valve job” should be part of any high-performance engine build.

Blow-down pressure is directly related to an engine’s compression ratio. A lower ratio tends to produce less blow-down pressure and because of this, a low-compression engine can usually benefit from greater exhaust airfl ow. An engine with a higher compression ratio has greater blow-down pressure, and air escapes more forcefully as the exhaust valve opens. It is this condition that gives high compression the crisp “pop” heard at the tailpipe. Low- and mid-lift exhaust airfl ow is very important. The quicker blow-down pressure can evacuate the cylinder, the less negative work the engine must perform as the piston travels upward during the exhaust stroke. That doesn’t suggest that peak isn’t important. The exhaust port is only a small portion of the entire exhaust tract, and there are other factors to consider such as diameter of the header tubes and the exhaust system beyond it.

The power of a particular engine that is exhaust fl ow defi cient tends to fall off rapidly. It’s diffi cult for an exhaust port to flow too well, but it can happen. The velocity of the exhaust charge exiting the engine creates a vacuum that draws the exhaust from the adjacent cylinders and header tubes. If exhaust tubing is so large that the charge isn’t able to maintain its velocity, an engine with excessive exhaust fl ow revs lazily and lacks strong low-end and mid-range torque.

High-Performance Valve Job

A high-quality valve job that includes multiple seat cuts generally improves airflow at every lift point, and the use of specific angles can bolster airflow in specific ranges. Pontiac originally used a 30-degree intake seat angle on its regular production, large-valve cylinder heads as it tends to enhance low-lift airflow. A 45-degree intake valve seat angle was common in such high-performance applications as the Ram Air V and Super Duty 455, where maximizing peak airflow was important.

Through the 1967 model year, most every cast-iron Pontiac D-port featured a fully machined “closed” combustion chamber. This design was effective early on but was eventually replaced.

A valve seat angle can accentuate the way airflow transitions from the intake port into the chamber. Selecting the best seat angle for a particular cylinder head casting largely depends upon the shape of the overall port shape, valve bowl area, and combustion chamber shape. The smaller bowl area associated with castiron originals tends to favor a 30-degree seat angle while a wider bowl area, such as that of the Edelbrock RPM favors a 45-degree seat angle.

A seat angle greater than 45 degrees is quite common when building race engines of other makes. At least one professional Pontiac engine builder says the gains are limited unless valve lift exceeds .700 inch. The tradeoff for peak airflow is significantly reduced low- and midlift airfl ow. Unless the cylinder heads are extensively ported and the engine will operate in a relatively narrow RPM range, a valve seat angle in excess of 45 is rarely required.

Combustion Chamber

The combustion chamber is an extension of the valve seat and the seat angles. The multiple cuts associated with a highperformance valve job can smooth the transition and improve airflow. A properly designed chamber allows airflow to smoothly transition from the port into the cylinder. A combustion chamber that shrouds the valves can restrict airflow as it expands, limiting airfl ow at all lift points. Original Pontiac cylinder heads contain a wedge-type combustion chamber that’s fully machined for a clean, consistent burn. All modern production engines, and most aftermarket Pontiac cylinder heads, feature a fast-burn combustion chamber, which is easiest identified by its distinct heart-shaped appearance. Both are very effective at providing strong performance, but the fast-burn chamber is clearly more effective.

Pontiac began widely using a wedge chamber with an “open” design in 1968. It improved airflow dispersion and flame propagation. Whether it actually improved performance is debatable, but Pontiac found it was more efficient and easier on tailpipe emissions.

Modern production vehicles use a fast burn combustion chamber for its excellent efficiency. The spark plug is located in an optimal position for maximum burn. Most aftermarket companies have incorporated a “heart-shaped” chamber into the castaluminum Pontiac V-8 offerings available today. It typically requires less total spark lead to produce peak power.

A fast-burn type of chamber is specifi - cally designed to agitate the incoming air/ fuel mixture, and the spark plug is strategically placed where combustion is most intense. The result is a highly efficient combustion event that, when compared to a typical wedge chamber, generally requires less spark lead to produce peak power, and can also require less fuel in the process. The latter is ideal for modern production engines where effi cient combustion can reduce tailpipe emissions.

Compression Ratio

There are two different compression ratio ratings associated with engines: static and dynamic. A static ratio uses the physical measurements of a particular engine to mathematically calculate an actual ratio. It uses such information as bore and stroke, piston-valve relief, deck-height volumes, head-gasket thickness, and combustion- chamber volume. Any change to static ratio involves replacing one or more of the aforementioned components.

Dynamic compression ratio uses the same variables to calculate as static ratio, but it also factors in cylinder pressure. During normal engine operation, there is a brief overlap period where both valves are open as the exhaust stroke ends and the intake stroke begins, and the cylinder cannot begin to pressurize during the compression stroke until the intake valve closes. Both conditions have a significant effect on dynamic compression ratio. Advancing or retarding the camshaft’s position in relation to the crankshaft will affect it.

Either compression ratio can be calculated using complex formulas. A quick search of the web provides several static ratio calculators on any number of auto enthusiast sites. Dynamic ratio calculators are more diffi cult to find, and require inputting detailed camshaft valve events. I commonly use the compression calculator on the Performance Trends Engine Analyzer program to calculate the static and dynamic ratios of various engines. It’s amazing to watch how small changes can affect compression ratio. When determining a target static compression ratio for an engine, there aren’t any negative attributes associated with increasing compression ratio so long as sufficient fuel octane is available. Compression adds horsepower and torque throughout the entire RPM range and it can make a given engine seem larger at low speed and can make the camshaft seem larger at high speed.

Some of Pontiac’s best flowing and most capable D-port cylinder heads were produced during the 1970s. They are low compression castings, however, and have rather larger combustion chambers. Your machinist can mill the deck surface to reduce chamber volume. Because the Pontiac V-8 is a 90-degree design, the intake flange must be milled an equal amount for proper port alignment.

In general terms, each .005 inch removed from a typical open chamber cylinder head reduces volume by 1 cc. Most agree that .060 inch is the most that can safely be removed from any unmodified casting. I have seen some milled as much as .1 inch for dedicated race engines, but I don’t recommend that for everyone. Physically measure chamber volume before and after machining for maximum accuracy. Do this with a graduated cylinder, or even a veterinary syringe and rubbing alcohol.

A fuel octane rating of 91 is the highest commonly available at gas station pumps today. The greatest compression ratio I am comfortable suggesting when combining cast-iron Pontiac cylinder heads with 91 octane fuel is 9.5:1. Like many others, I have pushed that toward 10:1 or slightly more without any negative effects in most instances, but detonation can destroy a fresh engine in short order. The fuel and spark curves and cooling system must be constantly monitored and maintained. The extra effort and risk may not be worth the slight power increase that results.

Cast-aluminum cylinder heads are very popular in modern builds. Quicker heat dissipation is one major benefit that aluminum castings offer over iron. Modern GM service literature states that aluminum can dissipate heat 2.5 times quicker than gray iron. That allows a cast-aluminum cylinder head to tolerate more compression before detonation occurs and most incorrectly assume that it automatically translates into a power increase. That’s not totally true, however.

The thermal efficiency of aluminum is less than that of cast iron. An aluminum casting allows a slightly greater amount of heat from every combustion event to dissipate into the coolant jacket surrounding the combustion chamber, and less of it is applied as force on the piston. Because of this, an aluminum casting typically requires at least .500 to .750 more compression to make power that’s equal to an iron casting. When combining a cast-aluminum Edelbrock RPM cylinder head with 91-octane pump fuel, I suggest a maximum target compression ratio of 10.25:1. The Performer RPM’s wedge chamber isn’t quite as efficient as a modern, fast-burn type found on other castings, and exceeding that ratio can induce detonation. If variables are closely monitored, I have seen some successfully push that toward 10.5:1, but once again, I feel the performance gain warrants the possible consequence.

Most every other cast-aluminum Pontiac cylinder head available on the aftermarket today features a fast-burn combustion chamber. These castings tolerate slightly more compression ratio. I recommend a target compression ratio of 10.5:1 when combining the Edelbrock Performer D-port or KRE D-port with 91-octane pump fuel. Some builders have reported successful results running a static ratio as high as 11:1, but I consider those specialized applications and certainly wouldn’t recommend that for everyone. A static compression ratio between 13:1 to 14:1 is quite common in race engines where 108- to 110-octane race fuel is used exclusively. It’s possible to push compression toward 14.5:1 or slightly higher, but the engine’s state of tune is extremely critical at this point, and there is very little margin for error.

Porting Advice

It’s not always possible to find an as-cast cylinder head with the proper amount of airflow and port volume for an application. Many professional Pontiac engine builders can supply a pair of cylinder heads that are tailored for your specific engine.

If you plan to port your own cylinder heads, there are several points to keep in mind. Airflow follows fluid dynamics and doesn’t like to change direction or compress or expand abruptly. The crosssectional area of an intake port should be as consistent as possible. The port should taper gradually toward the valve bowl. The transition from the valve bowl into the valve seat, and then as it expands into the combustion chamber, should be smooth and consistent.

Porting an original cast iron D-port is an easy way to increase airflow. Some hobbyists are willing to perform the task at home or pay for a professional service, but hand porting is not nearly as popular as it was in the past. There are too many high-flow aftermarket offerings at a reasonable cost available today.

When porting always remember that, generally, a larger port flows more air than a similar, but smaller port. You might assume that simply enlarging a port improves airflow, and that sometimes does result, but it’s important the additional port size is located in areas of the port where it can actually enhance airflow. If any portion of the intake port is stagnant, or has an area where port volume doesn’t have a positive effect on airflow, then a better-shaped, smaller sized port can, and often does, fl ow a greater airflow more consistently.

Cylinder Head Options

Not long ago the only cylinder heads available for the Pontiac V-8 were castiron originals. The market has exploded with cast-aluminum offerings in recent years and it seems as if there’s more than one option for a specific application today. The following is a buyer’s guide detailing the various castings and the applications each is best suited for.

Cast-Iron Pontiac D-Port

When Pontiac developed its 1955 287-ci V-8, its cylinder head featured a compact intake port that displaced slightly more than 150 cc. The small exhaust port featured a D-shaped outlet, and the center two exhaust ports were siamesed, allowing for a relatively small exhaust manifold package.

As engine displacement grew in the years that followed, Pontiac revised the intake port shape slightly and increased valve sizes to improve overall airflow. Though actual port volume remained near 153 cc, measured airflow from a typical D-port casting with a 2.11-inch intake valve peaked around 210 cfm at 28 inches. The combination maintained strong low-end torque, but improved the top end performance from the larger mills of the era.

Original Pontiac D-port cylinder heads are not overly difficult to find today. The small-chamber castings associated with the late-1960s performance era are rather rare and quite costly. Castings from the mid- to late-1970s “smog era” were once considered useless simply due to negative perception of any performance component of that period. Contrarily, the number-4X, -5C, and -6X castings make excellent, affordable choices for high-performance rebuilds. Low-performance applications from the late 1960s and early 1970s were fitted with smaller 1.96/1.66-inch valves and/ or pressed rocker arm studs. Peak intake airflow typically measured around 190 cfm. Your machinist can easily modify an original small-valve casting to accept larger 2.11/1.77-inch valves for a reasonable cost. It will quickly and easily boost airflow toward 210 cfm, and additional porting can significantly increase it beyond that. Your machinist can also convert any original-pressed-stud casting to threaded studs for minimal cost.

Most cast-iron Pontiac D-ports from 1968 forward are considered a viable option for performance use. The best feature 2.11/1.77-inch valves, threaded rocker arm studs, and six-bolt exhaust manifold flanges. Though fitted with 1.66-inch exhaust valves, the number-4X, -5C and -6X castings are some of the most affordable and commonly available.

Pontiac began identifying its cylinder heads with a secondary application stamp in 1973. Found on the vertical accessory boss located between the left and center exhaust ports, the most desirable stamps are “4” and “8.” A number-5C or -6X with a “4” has a 91- to 93-cc chamber while those with an “8” have a 100 cc chamber.

Some cast-iron Pontiac D-ports were equipped with 1.96-inch intake valves. That limits peak intake airflow to about 190 cfm at 28 inches of pressure. Modifying the intake seat to accept a 2.11-inch valve is a simple process that most machine shops can perform for a couple hundred dollars. It’s an easy way to increase peak airflow by about 20 cfm.

Pontiac commonly used pressed rocker studs on its low-performance applications. An aggressive camshaft can pull them out of the boss or cause the 3/8-inch bottleneck design to break off. A machine shop can pull the original studs and tap the bosses to accept oversized 7/16-inch rocker arm studs for about $100.

ARP number-290-7201 rocker stud kit is specifically designed for converting an original pressed-stud cylinder head to threaded studs. The ARP studs feature a typical 7/16-inch upper with a 1/2-20 base. The base threads are purposely left slightly long and must sometimes be trimmed to fit.

SD Performance has developed CNC porting programs for popular cast-iron Pontiac cylinder heads. Delivered fully machined and ready to install for a reasonable price, airflow increases toward 250 cfm at 28 inches in most cases. Optional porting takes that toward 280 cfm or slightly more. In my opinion, the CNC-ported cast-iron D-port is much more sensible and cost effective than attempting to port your own.

KRE developed a high-flow cast-aluminum D-port as a modern option for high performance street engines. The castings have been on the market for several years. Available bare or fully assembled, it is a popular option with hobbyists.

The KRE D-port includes a fast-burn combustion chamber that houses standard 2.11/1.66-inch valves. Offering more than 250 cfm of peak intake airflow and a small, compact intake port for strong port velocity, some companies are seeing as much as 340 cfm with aggressive porting and larger valve sizes.

The flow characteristic of the original D-ports are so similar that I suggest being less concerned with finding a specific casting number, and instead search for a casting that has the exact amount or slightly more chamber volume than what’s required to achieve your target compression ratio. Your machinist can easily mill the deck surface to reduce chamber volume or cut the valve seats for larger valves.

A typical D-port with a 2.11-inch intake valve can easily support just over 400 hp. Expect to spend several hundred dollars preparing a cast-iron D-port for a high-performance application; and that doesn’t include surfacing, valves, hardened valve seats, and a high-quality valve job or bronze valve guides.

Your engine builder can properly prepare your cast-iron D-ports for you, but in my opinion, one of the best options is from SD Performance. It has developed a number of CNC-based porting programs that increase airflow to at least 250 cfm, and to as much as 280 cfm depending upon the casting for a very reasonable cost.

Cast-iron D-ports remain popular with hobbyists building high performance engines on a budget, those racing in classes where original castings are required, or those who are simply Pontiac purists. Beyond that, it’s impractical to spend hundreds of dollars having a pair professionally ported and rebuilt. Any of the entry-level aftermarket Pontiac V-8 cast-aluminum cylinder heads flow nearly as much in as-cast condition and are ready to run, and can easily flow substantially more than a max-ported cast-iron D-port for a reasonable cost.

KRE D-Port

One of the most popular aftermarket Pontiac V-8 cylinder heads today is the cast-aluminum D-port developed by Kauffman Racing Equipment (KRE) in the early 2000s.

With 2.11/1.66-inch valves, peak intake airflow of the KRE D-port measures about 260 cfm at 28 inches of pressure and the exhaust flows more than 70 percent of that (about 185 cfm). Port velocity is an important factor in achieving strong low-speed performance for a street engine. KRE chose to limit intake port volume to 185 cc to promote good throttle response and high-torque output. Excellent peak flow allows it to consistently deliver 500 or more hp on moderate builds.

A key feature of the KRE D-port is its combustion chamber. The fast-burn design is similar to that of modern performance engines and promotes a quick and efficient burn. As-cast chamber volume measures 65 cc, but it can be CNC machined to 74 or 85 cc at an additional cost. Independent testing reveals that 30 and 32 degrees of total spark lead is all that’s required for maximum performance. For comparison, a typical Pontiac 6X casting requires 36 to 38 degrees to achieve the same performance.

Edelbrock has released its own cast-aluminum D-port. As part of its Performer line, the modern interpretation includes an exhaust crossover and is 50-state emissions legal. It boasts of improved oil drainages for quicker return to the pan.

The Edelbrock Performer D-port uses 2.11/1.66- inch valves and airflow peaks at approximately 260 cfm at 28 inches. The intake and exhaust valve bowls are blended by hand for maximum consistency and performance. The fast-burn combustion chamber is available in several sizes.

The KRE D-port is available fully machined, bare for professional finishing, or as complete castings that are ready to install. The latter includes stainless-steel valves and high-quality valve springs, bronze valve guides with Teflon seals, and 7/16-inch ARP rocker studs. A pair of as-cast KRE D-ports sells for approximately $2,000.

Though the KRE D-port was originally designed as a replacement for high-performance street engines, it’s proven its merit on street/strip and competition engines as well. Along with KRE, many Pontiac builders can boost peak airflow to 290 cfm and to as much as 340 cfm for a reasonable cost. Even at 340 cfm, they still bolt to any Pontiac V-8 block, use a typical Pontiac intake manifold, and do not require any offset rocker arms. The KRE D-port is extremely popular with performance enthusiasts. I consider the as-cast KRE D-port an excellent alternative to any cast-iron original. It’s much lighter and fits and installs just as an original. Overall airflow is substantially greater and it affords the distinct advantage of a modern fast-burn combustion chamber.

Edelbrock Performer D-Port

Edelbrock has produced its roundport replacement Performer RPM cylinder heads for several years, and it has been a very successful endeavor for the company. It recently ventured into the D-port market with the release of its castaluminum Performer.

Developed as its entry-level performance offering, Edelbrock’s Performer D-port installs onto any Pontiac V-8 just like a cast-iron original. Key features of its design include high-airflow capacity, a modern combustion chamber, and vastly improved oil drainage passages. A cost of about $2,200 per pair is quite reasonable.

The Performer D-port includes 2.11/1.66-inch valves. The as-cast intake port volume measures 204 cc, and it’s capable of delivering 260 cfm of peak intake airflow. The exhaust flows about 70 percent of that (182 cfm). After being on the market for only a few months, Pontiac professionals quickly increased peak intake airflow to 300 cfm, with the promise of 330 cfm or slightly more to follow.

Its heart-shaped combustion chamber is a modern, dual-quench design for maximum efficiency. It displaces 65 cc as cast, with 72- and 87-cc chambers available with CNC machining. Unlike the Performer RPM, where the larger chamber raises the valve seat and negatively affects the short turn transition, subsequently reducing airflow by several CFM at all lift points, Edelbrock increased the deck thickness of its 87-cc Performer D-port casting by .050 inch, which increases chamber volume without altering valve seat position. The Performer D-port is an excellent alternative wherever a cast-iron D-port is a consideration, particularly any application where a peak intake airflow boost is required. A variety of combustion chamber volumes allows it to produce a good compression ratio on most Pontiacs.

Find more tips like this in the book: HOW TO BUILD MAX-PERFORMANCE PONTIAC V-8 ENGINES

Learn more about super tuning Holley carbs. Get your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy and paste this link to share: https://www.cartechbooks.com/blogs/techtips/cylinder-heads-performance-guide-for-pontiac-v-8-engines

Pontiac Cast-Iron Round Port

For Pontiac to remain competitive in the late-1960s’ high-performance market, it recognized the need for larger, more powerful engines capable of continuous high speed operation. A series of new cylinder heads boasting of improved airflow were developed to substantiate strong top end performance. The castings were limited to the 1968½ Ram Air II, 1969– 1970 Ram Air IV, 1971–72 455 H.O., and 1973–1974 Super Duty 455 engines.

While the number-96 R/A II casting contains an intake port that’s nearly identical to the number-670 D-port, and subsequently flows around 210 cfm, the intake port volume of the R/A IV, 455 H.O., and Super Duty 455 was increased at least 170 cc, and even more depending upon the application. The larger port increases overall flow and cross-sectional area. Peak intake airflow measures around 240 cfm at .500- to .550-inch valve lift from the R/A IV and SD-455 castings, while the smaller 455 H.O. intake port peaks at slightly less. The round-port castings were coveted by racers for years, particularly the 1968½ R/A II number-96s, and the numbers- 722 and -614 from the 1969–1970 R/A IV because of their good fl ow characteristics and small combustion chambers.

During the high-performance craze of the late 1960s, Pontiac developed a series of high-flow cylinder heads with round exhaust port outlets. These round-port castings were originally installed on such engines as the Ram Air IV and Super Duty 455. They boast of improved intake and exhaust airflow, and remain very rare and desirable.

To maintain constant cross-sectional area within the SD-455 intake port, Pontiac widened it so much that the pushrod guide hole drilled into the casting broke through the sidewall of the intake port. A .030-inch sleeve was pressed into place.

The intake and exhaust ports of the Pontiac round ports were noticeably wider and larger than a typical D-port. The 1973–1974 Super Duty 455 casting (shown here) has a very smooth and contoured shape. Its intake port volume measures more than 185 cc and flows as much as 245 cfm at .550-inch lift.

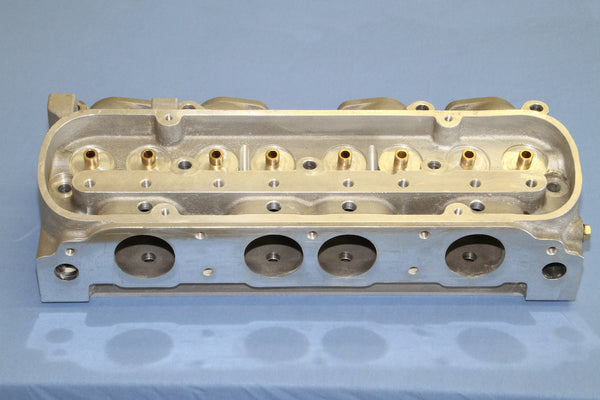

The cast-aluminum Performer RPM from Edelbrock is widely used by performance enthusiasts. Introduced in the 1990s as a high-flow replacement for the valuable Pontiac round-ports, its popularity and effectiveness hasn’t waned. It’s available semi-finished, fully finished but bare, and fully assembled and ready for installation.

The Performer RPM uses a wedge-type combustion chamber available in with 72 or 87 cc. Less efficient than a fast burn chamber, 36 to 40 degrees of total spark lead is commonly required to achieve peak power. Standard valve sizes are 2.11/1.66 inches and airflow peaks at about 280 cfm in as-cast form. Edelbrock hand blends the intake and exhaust bowl seats for improved airflow and consistency.

Many professional Pontiac engine builders offer a blueprinting service for the Edelbrock RPM at a very reasonable cost. It includes gasket matching the intake port, a 1.77-inch exhaust valve, smoothing and blending the intake and exhaust ports taking peak airflow toward 300 cfm, and custom-spec valve springs to match the camshaft. For the couple hundred dollars it adds to the cost of an otherwise complete casting, it produces one of the best performance values available today.

For engines that require additional airflow to reach a target horsepower peak, the Performer RPM can be modified for even greater flow potential. With a combination of a 2.19-inch intake valve and additional porting, many Pontiac builders offer Edelbrock Performer RPMs that peak at a minimum 330 cfm of intake airflow, and possibly slightly more.

A virgin pair of round-port cylinder heads can still bring several hundred to several thousand dollars depending upon the application and date code. Still able to provide stout performance, considering the rarity and expense of such castings, an original round-port is far more valuable to restorers than racers in today’s market.

Edelbrock Performer RPM

Edelbrock responded to the hobbyist need for a high flowing Pontiac V-8 cylinder head during the mid 1990s when it began producing its cast-aluminum Performer RPM. Over the years, the Performer RPM has proven itself as an excellent choice for high performance street and race engines alike.

The Performer RPM offers 280 cfm of peak intake airflow while exhaust peaks at nearly 70 percent of that (about 196 cfm). Edelbrock offers two distinct combustion chamber volumes: 72 or 87 cc. The larger 87-cc chamber relocates the valve seat and positions it higher in relation to the port floor. When compared to the 72-cc casting, airflow is negatively affected. The deficit is relatively minor, however, measuring no more than 10 cfm at any lift point. Intake port volume measures 215 cc. When compared to an original Pontiac D-port, that may seem excessively large. When you consider that most modern builds include at least a 460-ci engine, the cast port volume is adequate for strong peak horsepower, and nearly ideal for the larger 500-plus-inch engines that are so common today.

Edelbrock’s Performer RPM is available semi finished, fully machined but bare, and as complete castings ready to install. The semi finished offering requires professional finishing. The complete casting includes stainless-steel 2.11/1.66- inch valves, a single valve spring package that’s intended for a flat-tappet camshaft with as much as .575-inch valve lift, bronze valve guides, and 7/16-inch ARP rocker studs. Complete Performer RPM castings sell for approximately $2,000 per pair. That’s an excellent value for a high quality cylinder head that easily supports 500 hp out of the box and offers plenty of potential for future modifications.

Edelbrock says that it may someday update its Performer RPM, adding a modern, fast-burn combustion chamber. In the meantime SD Performance has improved its combustion efficiency by adding material to the as-cast 72-cc combustion chamber and CNC machining a heart shaped appearance. The result is a slight power increase with less total spark lead. The option costs a few hundred dollars.

Butler Performance and SD Performance maximize Performer RPM intake airflow with a “wide port” option (right). It peaks at 370 cfm or slightly more. Intake port volume is substantially greater. Intake manifold choice is limited to a few aftermarket units or a custom fabbed sheet-metal unit. Exhaust port configuration is unchanged, and remains a typical Pontiac round-port.

The KRE High Port was designed as a modern replacement for the Pontiac round port. Peak intake airflow measures 330 cfm as cast, but optional porting increases that toward 400 cfm. It uses a typical intake manifold and round-port exhaust headers.

The High Port has a fast-burn combustion chamber that’s CNC machined to 56 cc. Other chamber volume options include 64 and 80 cc. Standard valve sizes measure 2.20/1.70 inches with 2.25/1.75-inch valves optional.

The Tiger head from AllPontiac.com is popular with racers running the quickest. Peak intake airflow is greater than 410 cfm as cast. It accepts a traditional Pontiac intake manifold, but requires an intake flange adapter when using a typical intake manifold.

The Performer RPM is quite capable in as cast form, but professional engine builders have exploited its versatility for engines requiring substantially more airflow. For a performance goal greater than 500 hp, minor port cleanup that increases peak intake airflow to at least 300 cfm is available from most Pontiac builders for a few hundred dollars. The best options are those where intake port volume is marginally increased, maintaining strong port velocity and low-lift airflow. Exhaust fl ow is typically 70 to 75 percent of the intake.

Where the performance goal is 600 to 700 hp, peak intake airflow increases up to 330 cfm or slightly more are commonly available. Many Pontiac builders have developed complete Performer RPM packages that include additional machining and porting, over sized valves, specific valve springs, and lightweight valve train components for a reasonable cost. Butler Performance and SD Performance have developed a highly specialized Performer RPM for those seeking to produce as much as 900 hp or slightly more. The “wide-port” design features a large intake port that measures about 275 cc. Intake airflow peaks near 375 cfm, but the port is so wide at the entrance that the intake pushrod must be relocated. That requires a lifter with an offset pushrod cup, a rocker shaft system with intake rocker arms that are offset 1/2 inch or more, or both. Expect to spend at least $3,500 for a pair of wide-port castings plus the associated required components.

KRE High Port

Not long after KRE introduced its cast aluminum D-port, it developed an aluminum casting for larger displacement engines. The High Port is a high flow replacement that bolts to any conventional Pontiac V-8 block, uses the stock valve train configuration, and accepts any standard Pontiac intake manifold and round port exhaust header. Designed for a minimum bore diameter of 4.15 inches, the High Port uses 2.20/1.70-inch valves. The as-cast intake port volume measures 277 cc and airflow peaks at 330 cfm. The exhaust flows about 70 percent of that (about 230 cfm). Intake airflow of as much as 430 cfm is possible with additional porting and 2.25/1.75- inch valves, but it requires the use of a rocker shaft system with intake rocker arms that are offset at least .700 inch.

The Tiger head features a fast-burn chamber that measures 66 cc. No other optional volumes are available. AllPontiac.com recommends using dished pistons to achieve the target compression ratio. Standard valve sizes measure 2.25/1.80 inches.

The High Port combustion chamber is a modern fast-burn design. It’s CNC-machined and features a distinct heart-shaped appearance. Standard volume measures 56 cc, but various volumes up to 80 cc are available at additional cost. KRE offers its High Port bare, but with valve seats, bronze guides, and complete castings that include stainless-steel valves, valve springs compatible with a solid-roller camshaft, heavy duty valve train hardware, and 7/16-inch ARP rocker studs. A pair of complete castings begins at $2,500.

The KRE D-port may be a better choice for a moderately sized street engine, or even one that may see the drag strip occasionally. The High Port is ideal for max performance engines displacing at least 467 ci and where 625 hp or greater is the goal. With additional port work and the right combination of components, the High Port can sustain around 900 hp.

AllPontiac.com Tiger

Several years ago DCI Motorsports began developing a high-flow cylinder head that would allow large cube Pontiac V-8s to compete with similarly sized big block Chevys on the drag strip. When the project stalled, AllPontiac.com purchased the rights and tooling to the new Tiger head, and saw the aluminum casting into production during the mid 2000s.

The as-cast intake port volume measures 310 cc, and it peaks at 414 cfm of intake airflow. The exhaust port flows more than 70 percent of that (290 cfm). The Tiger head is available as a bare casting fitted with valve seats and bronze valve guides (but requires professional finishing) and a complete casting that’s ready to install. The bolt-on package includes 2.25/1.80-inch valves and a number of valve train options for moderate to high-lift roller camshafts. Though the Tiger head uses a typical Pontiac intake manifold arrangement, it has a much taller deck height, and that alters the point at which the intake manifold and cylinder head meet. AllPontiac.com offers its own 4-barrel Tiger intake manifold with extended runner length, or intake flange adapters to allow the use of a conventional aftermarket Pontiac manifold. Two distinct exhaust port configurations are available. One accepts a typical round-port tube header and the other features a raised-port design that requires a custom tube header.

The Wenzler Super Chief is a semi-finished head that requires professional finishing for its intended application. Intake airflow peaks around 320 cfm as cast, but as much as 430 cfm is possible with proper porting. The intake ports are so wide that a rocker shaft system is required.

The Super Chief has raised intake runners to improve airflow. The intake flange features a cast runner extension to allow the use of typical Pontiac intake manifold. It’s machined off when the Wenzler Gutsram intake manifold is used.

The Super Chief has a fast-burn combustion chamber that can be CNC machined to most volumes between 56 and 85 cc. You must specify the desired volume at the time of ordering. Otherwise your Pontiac professional can hand finish it for you.

The Tiger head features a fast burn combustion chamber that measures 50 cc in as cast form. The chamber of the complete casting is CNC machined and displaces 64 cc. Requiring a minimum bore diameter of 4.31 inches, the Tiger head is capable of delivering more than 900 hp on a typical 500-inch Pontiac V-8. Some of the fastest and most powerful Pontiac powered cars on the drag strip today are equipped with Tiger heads. Selling for about $6,000 per pair ready to install, they’re among the best performance value for your Pontiac V-8.

Wenzler Super Chief

Wenzler Engineering was among the first aftermarket companies to produce a cast aluminum Pontiac V-8 cylinder head when it introduced its original round port during the 1980s. Though still available as the “Series II,” the Super Chief is Wenzler’s high-flow offering specifically developed to extract maximum potential from a max-performance Pontiac V-8.

The Super Chief is available only in a semi-finished state. It is CNC machined and delivered with valve seats and bronze valve guides installed. The as cast intake port flows nearly 320 cfm of peak intake airflow, and with professional porting, the casting can deliver as much as 430 cfm, and possibly slightly more. The as cast exhaust port airflow is about 70 percent of the intake port (about 225 cfm), and responds similarly to professional porting.

Wenzler recommends using 2.25/ 1.80-inch valves when finishing the Super Chief. The intake bowl contains enough material to enlarge the intake valve to 2.30 inches for greater flow. Valve shrouding can be an issue when combining the recommended valve package with a bore diameter less than 4.25 inches, so Wenzler recommends at least 4.375 inches, but less may certainly be possible. The Super Chief also requires a rocker shaft system with offset intake rocker arms to accommodate the wide diameter intake ports.

The Super Chief is cast with intake runner extensions that allow the use of any conventional aftermarket Pontiac intake manifold. Wenzler also produces its Gutsram intake manifold specifically for the Super Chief. The exhaust port uses a typical round-port flange, but because its outlets are raised to improve airflow, a custom tubular header is required.

Wenlzer is a small company producing specialized cylinder heads for certain applications. It doesn’t advertise and may not be as well known as some of other larger companies producing aftermarket cylinder heads, but the Super Chief has proven itself as an excellent choice for serious performance. It has delivered nearly 1,100 hp when properly modified and offers excellent performance potential.

Edelbrock Pro Port Raw

Edelbrock’s Performer RPM was developed as a high-performance replacement for the original Pontiac round-ports, and significant airflow increases are possible with extensive modifications. Builders have maximized its flow limit, however. Edelbrock’s new Victor-series Pro Port Raw is its answer for the next level of Pontiac performance, and incorporates many design features for the future performance enhancements. When you’re a serious racer, cylinder heads almost always require some type of custom modifications and the Pro Port Raw is delivered semi-machined. In as cast form, its intake and exhaust ports are very small and completely unfinished. They must be ported by a professional to the desired shape and amount of airflow. Its combustion chamber is also unfinished and must be finished to the desired shape and size.

Edelbrock offers two distinct Pro Port Raw castings; valve angle from the piston center line is the difference between them. Reducing the valve angle influences airflow and certain racing bodies allow no more than a 2-degree variance from stock. For Pontiacs built from 1967 forward, the stock angle is 14 degrees and Edelbrock offers a Pro Port Raw with a valve angle of 12.6 degrees. The other casting features a valve angle of 11 degrees for those racing unrestricted.

The Edelbrock Victor-series Pro Port Raw is a new and exciting cylinder head for maxperformance Pontiac V-8s. It’s delivered minimally machined and must be completely finished for any application. Two distinct castings are available. One has a valve-topiston angle of 12.6 degrees and the other is 11 degrees.

The Pro Port Raw intake and exhaust ports are very small and completely unfinished (right). They must be professionally ported to the desired size and level of airflow (left). Intake airflow of 400 cfm is possible with either. The 11-degree casting accommodates 475 cfm or slightly more.

Like its intake and exhaust ports, the Pro Port Raw combustion chamber is also completely unfinished. The spark plug is pointed toward the exhaust valve for maximum efficiency. It can be finished with a heart-shaped or wedge-type chamber and any volume.

Roland Racing CV-1 features canted-valve angles. It requires a specific intake manifold, but uses a normal Pontiac camshaft layout and doesn’t require offset intake pushrods. The exhaust port uses a typical round-port header, and a common big-block Chevy valve cover or others from Roland Racing.

To improve airflow, Edelbrock lengthened the intake port of the 12.6-degree casting by 5/8 inch. The intake port of the 11-degree casting is lengthened 1.25 inches, which lends a tunnel port effect, significantly improving airflow and performance. With typical port work, Edelbrock reports that the 12.6-degree Pro Port Raw intake port can deliver at least 360 cfm with 2.19/1.74-inch valves and it has seen with as much as 420 cfm. At least 400 cfm is available from the 11-degree casting with as much as 475 cfm possible with additional porting. Even with the added intake port length, Edelbrock specifically designed its Pro Port Raw to accept a traditional Pontiac intake manifold. Depending upon the amount of porting required to attain the desired amount of airflow, the Pro Port Raw uses a typical pushrod location and stud mounted rocker arms. Offset lifters and a rocker shaft system is required for maximum airflow efforts, however. The exhaust uses typical roundport tube headers.

The Pro Port Raw is for serious racing applications that require maximum airflow from the cylinder head package that uses a typical intake port configuration and valve train configuration. As of this writing, distribution from Edelbrock is limited, but with a suggested minimum bore diameter of 4.18 inches, it is sure to be an excellent choice for most engines of 460 ci or greater, and should give stunning results.

Roland Racing CV-1

When developing a high-flow aftermarket cylinder head, the diameter of the intake and exhaust valve package is limited by bore size. The closer the valves are to the cylinder walls, the more shrouding that occurs, which can negatively impact airflow. Canted valve angles, where the intake and exhaust valves slightly oppose and point toward the cylinder center line, allows for larger valves while lessening the risk of shrouding, maximizing airfl ow and performance. Chevy used canted valve technology when developing its big-block, and there are a great number of aftermarket companies producing canted valve cylinder heads for many makes. It wasn’t until Roland Racing released its cast-aluminum CV-1 in the 2000s that canted valve technology was available to Pontiac hobbyists.

The CV-1 intake port measures 285 cc and is capable of flowing 380 cfm as cast. The exhaust port flows about 70 percent of the intake (about 265 cfm). As delivered, it uses 2.25/1.66-inch valves, but the CV-1 has extra material cast in for professional porting and additional airflow. It can easily accommodate 2.30/1.71-inch valves and a peak intake airflow increase to 440 cfm. Complete castings, which include quality stainless-steel valves and conical valve springs, sell for $3,000. As the first canted valve cylinder head developed for Pontiac V-8s available on a mass scale, the CV-1 easily bolts to any traditional or aftermarket.

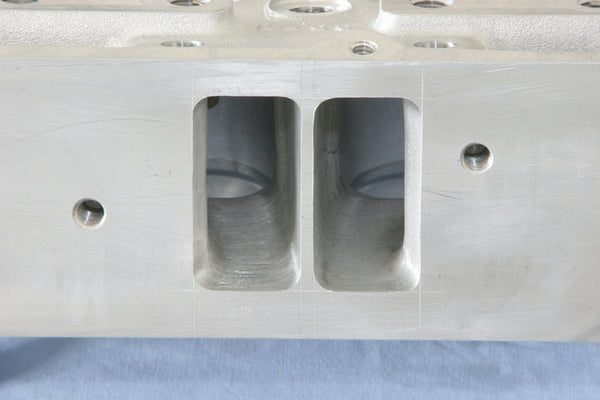

The CV-1 has unique rectangular intake ports that measure 285 cc and flow 380 cfm as cast. Ideal for larger engines, plenty of material was cast into the cylinder head for professional porting. Roland Racing offers a second CV-1 with a 215-cc intake port for smaller engines, or for those that want their CV-1s professionally finished elsewhere.

The CV-1 features a CNC-machined, fast-burn combustion chamber that measures 65, 81, or 92 cc. Standard valve sizes measure 2.25/1.66 inches. Special pistons are required for proper piston-to-valve clearance.

Pontiac V-8 block with a bore diameter of at least 4.15 inches. Its canted-valve design requires a unique intake manifold arrangement, and Roland Racing offers several proprietary options at extra cost. The exhaust port uses a typical roundport exhaust header, but the port can be milled away for applications that require the additional clearance. It has taken a while for its popularity to catch on, but with some noticeable success on the dyno and drag strip, the CV-1 has gained notoriety and proven itself as a viable option for any maxperformance Pontiac V-8. The relatively large intake port and high airflow tend to produce broad power from 4,000 rpm toward 7,500, with horsepower generally peaking around 7,000 rpm depending upon the application. A cantedvalve cylinder head may not be for every enthusiast, but it’s certainly an option if maximum performance is the goal.

KRE Warp-6

With its successful cast-aluminum D-port and High Port cylinder heads already on the market, KRE has recently introduced its new canted-valve Warp-6 casting. At the time of this writing, it’s so new that there hasn’t been a great deal of independent testing performed, but KRE’s internal testing indicates that it’s very capable. More than 1,100 hp was achieved using as-cast Warp-6 heads on a 535 inch on KRE’s dyno.

A key component in its astounding performance is its symmetrical valve arrangement. Unlike a traditional Pontiac cylinder head, where intake runners share a common wall, the center exhaust ports are siamesed, and some intake and exhaust ports flow better than others, the Warp-6 ports are located in the same relative position regardless of the cylinder and each intake and exhaust port offers the same level of airflow. The design advantage improves cylinder-tocylinder consistency and overall engine performance.

The Warp-6 casting is available fully machined, but bare, and completely finished and ready to install. The casting is designed for standard 2.25/1.75-inch valves. Intake port volume measures 399 cc and offers 460 cfm of peak intake airflow as cast. The exhaust port flows about 70 percent of that (about 320 cfm). It can accommodate up to 2.40/1.85- inch units and at least 515 cfm with professional porting. Complete castings include titanium valves, specifi c springs for .900 inch of roller cam valvespring lift, and other quality valvetrain components. The fast-burn combustion chamber is CNC machined and measures 60 cc.

In addition to flow balance, the symmetrical valve arrangement also eliminates the siamesed exhaust valves from the center cylinders of each bank. Typically an area of extreme heat, particularly on highend race engines, the heat can comprise the gaskets ability to maintain proper cylinder seal, ultimately leading to complete gasket failure. The symmetrical arrangement allows heat to dissipate evenly across the casting, improving gasket life.

Because of its unique valve arrangement, the Warp-6 requires a specific camshaft with proper lobe placement and a complete rocker shaft system that KRE developed in conjunction with T&D Machining. The exhaust ports require custom tube headers that measure more than 2 inches in diameter. KRE also offers specific intake manifolds, valve covers, and a coolant crossover water manifold, all of which are required for the Warp-6. Unfortunately, you cannot simply install the Warp-6 casting and all its related components on to an existing Pontiac V-8 without major disassembly. The Warp-6 requires custom pistons with valve pockets strategically cut into the crown for proper clearance, and KRE can provide them for you. It may be best to dedicate a specific build to the Warp-6 if you plan to use them on your project. It looks to be a casting we can expect much from down the road.

Reproduction Ram Air V

Pontiac developed tunnel port cylinder heads for a group of new highperformance engines displacing 303, 400, and 428 ci. The 400-ci Ram Air V was very close to reaching production in 1969 before the tunnel port program was scrapped entirely. Pontiac estimates that about 200 pairs of 400-ci cylinder heads were produced at the time, and they remain very rare and quite valuable.

The KRE Warp-6 is a recent offering in the canted-valve market for Pontiac V-8s. Its symmetrical valve configuration and port design provides maximum port consistency for greater performance. The valve arrangement reduces the excessive heat that builds between the siamesed exhaust valves on traditional castings that cause head gasket failure.

The Warp-6 fast-burn combustion chamber measures 60 cc. Peak intake airflow measures 460 cfm with standard 2.25/1.75-inch valves. That can increase to at least 515 cfm with optional porting and 2.40/1.85- inch valves. All associated components such as intake manifolds, header flanges, and valve covers, are available from KRE.

McCarty Racing has recently introduced its reproduction Ram Air V casting. Like the original, the reproduction features individual exhaust ports that require custom-made tube headers. It’s compatible with any 400 or 455-ci Pontiac block and most any aftermarket unit. Specific fasteners are required and McCarty Racing can provide them.

The Ram Air V was a tunnel-port engine that Pontiac developed during the late 1960s. It features large, round intake ports that have the pushrod running directly through the center. McCarty Racing’s cast-aluminum reproduction mimics the original in nearly every respect, but the intake and exhaust ports are designed for improved airflow and the casting is generally beefier throughout. The pushrod’s pressed guide tubes are missing from this preproduction example.

Hedging on the R/A V mystique, McCarty Racing developed a new tunnel- port Pontiac casting constructed of cast-aluminum that bolts to any stock or aftermarket Pontiac block but features a number of design improvements. At the time of this writing, McCarty Racing is finishing up its plan for complete bolt-on assemblies, so the final airflow numbers and valve size specifications are not yet finalized. Expect pricing to begin around $2,500 per pair and many options are available. A specific intake manifold and headers are required, both of which McCarty can provide at extra cost. It is best to contact the manufacturer for further details.

Written by Rocky Rotella and Posted with Permission of CarTechBooks

If you liked this article, you will LOVE the full book!

Get your copy here.