Oldsmobile Cylinder Head Guide

by Bill Trovato

The traditional Oldsmobile V-8 is unique, in that both small- and big-block versions can share the same cylinder head castings. While few would ever recommend bolting small-block heads on a big-block engine, using the big-block heads atop a small-block bottom end is a cool hot rod trick. So, which heads are the best performers, and how can you spot them?

The Oldsmobile factory-production small-block cylinder heads are identified by a number cast into the front lower portion of the head next to the number-1 and number-8 cylinders. The oldest castings have a lower number and the latest production castings have a higher number. All of the small-block combustion chambers have roughly the same shape, but vary in volume. The same goes for the intake and exhaust ports on the muscle-car-era castings. They did change quite a bit in the later smog engine years. These castings are undesirable for performance use. These cylinder heads can certainly be made better with some work, but it is generally best to use the older castings.

This tech tip is from the full book, OLDSMOBILE V-8 ENGINES: HOW TO BUILD MAX PERFORMANCE.

For a comprehensive guide on this entire subject you can visit this link: LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook Groups or Forums/Blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.cartechbooks.com/blogs/techtips/factorysmallblockcylinderheads

The factory iron small-block cylinder head has some very small intake ports and is very plain to see.

The most desirable small-block Olds cylinder heads are the number-6 and number-7 castings.

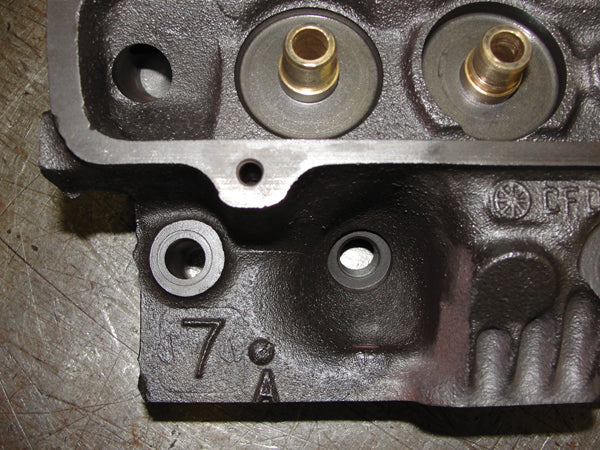

Oldsmobile small-block cylinder heads have a number, like this popular number-7 casting cylinder head.

The most common modification done to these small-block Olds castings is to install the 2.000-inch-diameter intake and 1.625-inch- exhaust valves from the big-block. With the right seat cutters, the bowl is larger and the bowl shape allows a better transition for the air/fuel mixture to exit the valve, thus increasing available horsepower. Installing these larger valves should be standard procedure, even for stock rebuilds. Stock-type steel big-block Oldsmobile valves are available through SBI and other sources and are relatively inexpensive. This modification is easily performed during the valve-job operation and turns an old, rusty, worn-out cylinder head with pitted seats into a set that is in brand-new condition.

If you want a free port job on your small-block Olds heads, put the die grinder down. Get big-block heads, mill the deck surface so you can get the combustion chamber volume, and presto! you have a ported head.

Factory Big-Block Cylinder Heads

Oldsmobile factory-production big-block cylinder heads are identified by a letter cast into the front lower portion of the head on the number-1 and number-8 cylinders. The oldest castings (used on the 1965 400– to 425-ci engines) have the letter “A,” and the latest big-block production castings have the letter “J.” The series ended there. I have not found any considerable difference between the castings, with the exception of the “J” heads. They definitely have the smallest runners of the bunch, and are a poor choice for performance use, even with porting. So remember: “J” is for junk.

This factory iron big-block “A” cylinder head has the largest ports I have seen. If you bolt a set of big-block heads on a small-block, it’s like bolting on a ported head. Some manifolds may not have enough material and runner volume to match, but the Edelbrock Victor (PN 2812) does.

In years past, I measured intake runner volume in a bunch of different-lettered iron cylinder heads, and found that the “E” castings were second in line to the “J” heads in small runner size. The “E” castings are smaller than the others, but only by a few cubic centimeters. The famous “C” head is well known for being the best factory iron cylinder head to use, but I have not found that to be the case. Of all the factory iron heads I have played with, I have found the “A” heads to be the best in stock form. In my experience, it seems that the rest of the factory cast-iron cylinder heads (A through H) are close enough in runner shape and size so that it does not really matter which one you select for your high-performance Oldsmobile project, especially if you are porting them.

This tech tip is from the full book, OLDSMOBILE V-8 ENGINES: HOW TO BUILD MAX PERFORMANCE.

For a comprehensive guide on this entire subject you can visit this link: LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook Groups or Forums/Blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.cartechbooks.com/blogs/techtips/factorysmallblockcylinderheads

These Hurst Olds “D” heads are some of the rarest Olds heads. The 1972 W-30 “H” heads are probably the rarest; the 1970 W-30 “F” heads are not quite as rare.

Filling the exhaust heat crossovers can never hurt. The nice job on these “C” heads came by pouring in melted aluminum from the port side and then porting the bowl properly. Notice the shape of the port under the intake seat.

Another method of blocking the exhaust crossover is to machine a pocket on the intake side and press fit or silicone a piece of metal in there.

Head Gaskets

Back when I ran the NHRA Stock Eliminator W-30 engine, I used the factory .017-inch embossed steel shim head gasket. That gasket performed very well at 11:1 compression and I never had a gasket failure. Unfortunately, they are not available anymore. Luckily, I saved all of my used ones and reused them by glass-bead cleaning them and gluing a .015-inch-thick soft copper wire around the raised combustion ring. They worked like a charm.

The obsolete factory Oldsmobile big-block .017-inch-thick steel shim gasket worked very well in my 11:1-compression NHRA Stock Eliminator engine.

There are a number of head gaskets for the Oldsmobile engine. The most popular for street applications are: the FelPro PN 8171 PT1; the FelPro PN 1155; and the Corteco PN 55660HG in .040-inch-thick and PN 55661HG in .028-inch-thick versions.

I wouldn’t say these gaskets are the best choice for aluminum heads. I have had various issues with them. I don’t know whether the power levels just happened to be greater on the aluminum-headed engine, making that the ultimate cause of failure, or the fact that the heads were made of aluminum. I don’t really know, but when I have an issue with something, I don’t use that product again. I don’t have time to figure out why some company’s product failed, especially when there is something else I can get my hands on that performs reliably. But I have not had a failure with these gaskets on cast-iron cylinder-head engines.

Corteco makes some high-quality gaskets. They are available in .028 and .040 thicknesses. I only use these on cast-iron head engines. I have seen very slight water seepage on engines using aluminum heads.

The best head gasket in 98 percent of high-performance Oldsmobile applications is the Cometic MLS head gasket (multi-layer steel). These gaskets basically consist of two layers of embossed hardened steel and a shim of desired thickness between. This design allows you to select a wide array of thicknesses for the application. I have seen many engines use these in very-high-horsepower turbo and blower applications with varying degrees of success. When they do fail in these applications, it usually ruins something like the block or the cylinder head. These MLS gaskets are made to order from Cometic and take about four weeks to produce. These gaskets are pretty much available in any thickness and bore size when you custom-order them. BTR stocks the commonly used thicknesses, and they are available in .027-, .030-, .036-, .040-, .045-, .051-, .060-, .065-, .071-, .074-, and .120-inch sizes.

Multi-layer steel gaskets made by Cometic are the ultimate in combustion sealing. They require that the decks be flat and smooth. Don’t stress out over the finish; just leave no rough cuts. I have reused them multiple times by carefully cleaning them and applying a very light layer of silicone over the entire gasket.

The ultimate setup in cylinder sealing is the copper head gasket with a stainless O-ring embedded into the cylinder head, with a corresponding receiver groove machined in the block. When a Top Fuel car uses a method other than this to seal combustion pressure, I’ll try it. Until then, my serious engines are sealed by this method. Copper head gaskets get a bad rap from people, mostly because the O-ring job was performed incorrectly, allowing coolant into the engine. This happens either because the combustion seal is compromised or the head does not sit flat due to improper machining. Trust me, when the job is done properly, there aren’t any sealing issues in the highest-horsepower applications.

Copper head gaskets can be purchased from numerous suppliers such as Clark, Hussey, SCE, and Flatout Gaskets and should be ordered with a gasket-bore size .050-inch larger than your engine bore. I personally prefer the gaskets from Flatout; they are made to order with any bore size and configuration, and are made and shipped within a few days.

When performing the O-ring and receiver-groove operation, location of the O-ring and receiver groove is absolutely important. They must line up perfectly to each other. When BTR performs this operation, the O-ring and receiver grooves are located off of the cylinder head and block dowel pins, and are machined on a Cincinnati CNC machine, which makes it easy to get perfect. The cylinder head is machined so that the stainless .041-inch-diameter O-ring protrudes .015 inch up from the deck, and the corresponding .040- to .060-inch-wide receiver groove is machined at the same depth into the block.

There is not a better method of sealing combustion than the copper head gasket with the proper O-ring and receiver grooves machined into the head and block. It is the same method used by 5,000+-hp NHRA Top Fuel cars.

When you remove a cylinder head torqued up with a copper head gasket, you literally have to pry the gasket off the block because the soft copper embeds into the receiver grooves, which is what seals the combustion pressure. Don’t ever let anyone tell you that you don’t need a receiver groove in these copper head gasket/O-ring applications. You do.

O-rings can be installed in the head or the block, but preferably in the cylinder head.

The Milling Process

Milling cylinder heads for increased compression is a relatively easy operation because Oldsmobile cylinder heads are square and can easily be cut without any special fixturing. I have milled factory iron, Batten, and Edelbrock Performer RPM heads as much as .100 inch for certain applications. The lowest combustion chamber volume I ever had on an Edelbrock Performer RPM head with the standard combustion chamber was on the 2009 Engine Masters Challenge engine at 46 cc. With a range of 77 cc to 46 cc, you should have a variety of compression ratios available for your simple mill job.

Even at that small 46-cc level, the cylinder head seemed to have adequate deck thickness for the 640 hp that the particular engine produced. The deck thickness and stiffness required on the cylinder heads has to be determined according to the amount of horsepower the engine can produce. When milling your cylinder heads, make sure that the machine shop machines the deck surface parallel to the valve-cover rail. This ensures that the valve free-drop and combustion-chamber depth is even. I have seen many heads that have been milled unevenly, which throws everything off. So give your heads a check with a set of vernier calipers to make sure that the deck surfaces are parallel to the valve-cover rail and the same as each other. This tells you if both heads are milled the same amount and if those decks are straight.

When milling to reduce the combustion-chamber volume, it takes approximately .006 inch of deck surface removed per cubic centimeter of reduced combustion-chamber volume. This method brings you pretty close. If you need it to be more exact, you have to check multiple times, as the head is shaved.

This tech tip is from the full book, OLDSMOBILE V-8 ENGINES: HOW TO BUILD MAX PERFORMANCE.

For a comprehensive guide on this entire subject you can visit this link: LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook Groups or Forums/Blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.cartechbooks.com/blogs/techtips/factorysmallblockcylinderheads