Ford AOD and 4R70W Transmission History and Evolution

The History & Evolution of the Ford AOD and 4R70W Ford Transmissions

Since their introduction by Ford in the 1980s, the AOD, and later the 4R70W, have helped set the standard for modern transmissions. Steadily increasing fuel efficiency and more comfortable cruising capabilities have kept these overdrive transmissions popular more than 40 years later, and they aren’t going away anytime soon.

Even enthusiasts of pre-1980s cars are fans of the AOD and 4R70W transmissions, swapping out their older parts to gain the benefits of overdrive in their classic chassis. Anyone with an AOD, AODE, or 4R70W transmission in their car—or anyone interested in swapping one into their vehicle of choice—should check out Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70W for a comprehensive guide on rebuilding, modifying, and reinstalling these great transmissions.

Buy the full book here!

If you’d like to get a head start on your reading, check out this excerpt on the history of the AOD and 4R70W transmissions.

Ford AOD and 4R70W Transmission History and Evolution

The prosperous postwar years provided time to forget about the Great Depression and fuel/material shortages. We became wasteful in the years following World War II because fuel was in plentiful supply. Gas wars were common, with fuel at giveaway prices. Overdrive, which had been quite common prior to World War II, faded away amid cheap and plentiful gasoline and low-buck engine overhauls.

When the Arab Oil Embargo unfolded during the winter of 1973–1974, it was a rude awakening for spoiled American motorists. Large-displacement carbureted V-8s, heavy automobiles, and 2- and 3-speed straight-drive automatics came with a price at the pump. Fuel had long been cheap and plentiful, and it was a great ride while it lasted. However, what seemed short-lived would be our ultimate destiny: higher fuel prices. When the second oil cri-sis arrived in 1979, it brought with it increased fuel-economy standards imposed by the federal government. This time Detroit was ready with more-fuel-efficient automatics with direct mechanical lockup torque converters. And Ford was no exception.

Ford’s Automatic Overdrive (AOD) entered service in 1980 in full-size Fords, Mercurys, and Lincolns. What makes the AOD rugged is its geartrain, consisting of a Ravigneaux compound planetary gearset borrowed from the older, time-proven MX, FX, and FMX transmission family. Ford fitted these internals to a fresh cast-aluminum case with an overdrive unit.

Ford’s fuel-efficiency approach began first with locking torque converter 3-speed automatic transmissions such as the Ford C5, which was an updated version of the venerable C4. Chrysler did the same thing with its 904 Torqueflite with a locking converter and its “Lean Burn” electronic engine/powertrain control system in the late 1970s. General Motors joined the crowd with its Turbo 200 and 200-4R.

The AOD

Ford’s automatic overdrive (AOD), first introduced in 1980, was the first domestic automatic overdrive transmission. General Motors and Chrysler swiftly followed. Chrysler added overdrive units to existing 3-speed automatics: the 904 and 727. General Motors further developed the 200 into a 200-4R with overdrive, and from there the all-new 700-R4 purpose-built automatic overdrive.

Although the automatic overdrive might seem intimidating when compared with older C4, C6, and FMX 3-speed automatics, there’s really nothing to it aside from add-on hydro-mechanicals and direct overdrive lockup to eliminate wasteful slippage.

Ford’s all-new AOD in full-size Fords, Mercurys, and Lincolns was a fresh design, yet it incorporated existing tried-and-proven Ravigneaux geartrain components borrowed from the BorgWarner FMX parts bin. The AOD is rugged and dependable thanks to the use of these time-proven components. It took quite a few years for Ford to get the AOD dialed in to be a solid performer, however, and this occurred with help from the aftermarket and off-road racers. The AOD had durability problems, most notably in the overdrive unit, which was a new design using unproven components. Ultimately, the 1993 Lincoln Mark VIII AOD Electronic Control (AODE)/4R70W’s wider overdrive drum and band solved the problem.

This is the AOD passenger’s side with dipstick tube access, cooler line connections, and pressure ports. As you can see from the case design, the AOD has two servos and bands with an accumulator at the rear. From left to right in the case are the shift accumulator (A), low-reverse band servo (B), and overdrive band servo (C). All are accessed by pulling the pan and valve body. Because the AOD has an integral bellhousing, it is limited in application. Adaptor kits are available for the AOD for the FE-series big-block, the Y-Block, Bronco, older F-Series, and more.

The driver’s side of the AOD shows the linear multi-pin connector backup light and neutral safety switch (A), the manual shift lever pointed downward at 7 o’clock (B), and the dogleg TV cable connection (C). The bell-housing threaded boss is for the TV cable linkage from the engine.

Here are the dipstick tube (A) and cooler line (B) ports. The AOD dipstick tube clears most firewalls on classic vehicles such as the Mustang, Cougar, Fairlane, Torino, F-Series trucks, and Broncos. Aftermarket dipstick tubes fi t those vehicles if stock tubes won’t.

The AOD’s torque converter and bellhousing are designed for a 164-tooth flexplate, a small-block V-8, and large 6-cylinder blocks. AOD torque converter installation is tricky. You must confirm that it is fully seated on the two input shafts and the front pump drive. If it isn’t fully seated, you can expect extensive damage and transmission failure.

The AOD has two input shafts: a large hollow main input shaft and a smaller solid overdrive/torque converter lockup shaft, which is more for light-duty cruising once you get up to speed. The largest outer shaft is the torque converter’s stator support and it does not rotate.

Ready to get started on rebuilding your AOD? Pick up your copy of this book now!

This is the smaller solid overdrive/locking converter input shaft, which transfers power to the overdrive unit in lockup only. What makes torque converter installation so important is getting the torque converter fully seated on the stator, main input shaft, and this smaller lockup shaft. The converter must also fully seat into the front pump drive rotor. It is all performed by feel.

The AOD’s Ravigneaux compound planetary gearset is the old-school, tried-and-proven durable geartrain borrowed from BorgWarner’s cast-iron FMX transmission. The Ravigneaux gearset is the workhorse that does the work of two planetaries.

This is the AOD’s stamped-steel pan with the words “Automatic Overdrive” and “Metric” for quick identification. The AOD pan is shaped differently from the AODE/4R70W pan and does not interchange.

More than 30 years into its service life, the AOD has proven to be an outstanding transmission for street and strip use thanks to effective engineering refinements. Vintage Ford enthusiasts love the AOD for its simplicity, durability, and an array of installation kits available in the aftermarket. California Pony Cars, in particular, offers everything you need to swap the AOD into a classic Mustang. There’s also Performance Automotive Transmission Center (PATC), which offers a variety of AOD and 5R55 swap kits and parts. Speedway Motors has swap kits for the Ford flathead V-8. Bronco Grave-yard is yet another source. There are several sources that enable you to put the AOD behind an FE big-block.

The AOD is a true hydromechanical 4-speed automatic transmission controlled by a manual shifter and throttle valve (TV) cable. The TV cable, tied to the vehicle’s throttle linkage, works like a kickdown linkage, yet it is more finite in its execution because it does the work of both a kickdown (downshift) linkage and vacuum modulator used on earlier Ford automatics. There is no vacuum modulator or kickdown linkage with the AOD as we see with the older C3, C4, C6, and FMX transmissions; only the lone TV cable.

Interested in all things Ford? Check out these other books!

The C3, C4, C6, and FMX transmissions have vacuum modulators to control shift-points, depending upon throttle position and manifold vacuum. They also have a throttle-controlled kickdown linkage, which works with the vacuum modulator to control shift-points mostly for wide-open throttle (WOT) downshift. The vacuum modulator finitely controls line pressure. The kickdown delivers maximum line pressure at WOT. The AOD eliminates the vacuum modulator by relying strictly on throttle position via the TV cable to control shift-points. Proper adjustment of the TV cable is crucial. Improper adjustment can lead to transmission failure, which means it must be performed strictly by the book to prevent slippage and clutch/band failure.

Here’s the AOD’s Ravigneaux gearset as viewed from inside where planet gears wrap around the sun gear (not shown) and shell. This stamped assembly, known as the center support, supports the geartrain.

With a Ravigneaux compound planetary gearset, load is distributed across a broad surface area for smoothness and less wear. It also has the benefits of two gearsets in one, which offers some weight reduction and engineering simplicity (with fewer parts).

The AOD’s internals: main input shaft, reverse clutch drum (overdrive band), forward clutch, and direct clutch cylinder. This is how they go together and fit into the transmission case

The AOD’s forward clutch assembly is driven by the main input shaft. On the bench is the direct clutch, which delivers power to the output shaft.

The AOD’s cast-iron and steel gear pump provides hydraulic control pressure and lubrication. Included with the front pump is the intermediate clutch piston, which holds the forwardmost clutch pack in the case immediately behind the pump.

The AOD’s front pump case casting number tells you which front pump you have. Although there were virtually no engineering changes to this pump during its production life, there are variations in this casting number, depending upon when it was cast.

Here, you can see the difference between a standard AOD reverse drum (right) and the 1993-up Lincoln AODE/4R70W reverse/overdrive drum (left). The wider Lincoln reverse drum and overdrive band hold better due to increased surface/friction area. The wider reverse drum/overdrive band is what you want for any AOD build because of its greater holding power and reduced chance of failure. Never use the wider band without using the wider drum.

The AOD’s valve body didn’t change much throughout its production life. What makes it different from the AODE/4R70W valve body is its throttle valve function rather than computer control.

Look for the Ford casting number on main cases and valve bodies for an indication of when the part was produced. This is a 1980 AOD RF-E0AP-7A092-AF valve body.

Here’s an RF-E9DP-7006-AA AOD main case, an engineering revision time frame of 1989. “RF” is believed to mean Rouge Foundry (Dearborn, Michigan).

This AOD tailshaft housing with RF-E0AP-7A040-BD indicates a 1980 original casting from Rouge Foundry. The “E0AP” part of the casting number doesn’t always mean it was cast in 1980; it means there were no engineering changes since 1980. The number “25” here is the cavity number, which indicates which sand-cast mold the piece was cast from. In other words, a bunch of identical sand-casting “cavities” were used on cast-iron or aluminum parts in mass production. Cavity numbers help the foundry find any casting issues. On main AOD cases, you find the cavity number on the bellhousing.

This is the multi-pin backup light/neutral safety switch for AOD only. It is a linear switch operated by a cam on the manual shift linkage inside the case. It prohibits starting in any drive gear range and illuminates the backup lights while in reverse.

On the backup light/neutral safety switch, the copper pin rides a manual shift linkage cam that moves the pin in linear fashion to open the start circuit or fire the backup lights. This switch is available from Late Model Restorations (PN SW2276). The harness and multi-pin plug is available from Ron Francis Wiring (PN PG-057).

The AOD is an old-school automatic with hydromechanical function and a conventional tailshaft flyweight valve governor that affects upshifts and downshifts based on vehicle speed. It has a direct effect on control pressure and shift-points. This governor is calibrated to vehicle weight and size, which means there are variations that you need to be aware of, especially if you’ve purchased an AOD core of unknown origin.

This disassembled AOD governor demonstrates function. From left is the (A) plug, (B) sleeve, (C) spring and retainer clip, (D) valve piston, (E) screen, and (F) main governor body with cover plate. The counterweight is not shown, but it houses the valve assembly and counter-weights the complete assembly. The governor valve piston is spring loaded and operates against both spring load and centrifugal force. As the output shaft spins faster with vehicle speed, the valve piston overcomes spring pressure and line pressure goes to work. This affects shift-points as well as throttle valve movement. It also affects both upshift and downshift points. Use a stiffer spring and you get a higher shift-point. Calibration is based on spring pressure.

The AOD is equipped with two friction bands and clutch drums: one low-reverse band and clutch drum and one band and clutch pack for overdrive. There are also two one-way clutches, and four friction clutches. The geartrain consists of a Ravigneaux compound planetary gear package also used in the FMX, MX, and FX transmissions employing two sun gears and a dual pin-ion set that provides four forward gears and one reverse. This makes the AOD a tough competitor in the complicated world of automatic overdrive transmissions.

Because most AOD transmissions have the six-bolt bellhousing design first introduced for 1965, they fit behind any small-block V-8 or large 240- or 300-ci 6-cylinder engine. Smaller five-bolt bellhousing V-8s prior to 1965 do not bolt to the AOD. However, there are aftermarket adaptor kits that allow you to bolt the AOD, AODE, and 4R70W to big-block Ford V-8s. This means the AOD has become one of the most trusted automatics in history.

The easiest way to identify the AOD is the “Automatic Overdrive Metric” wording along with the Ford Blue Oval stamped into its 14-bolt galvanized steel pan. The AOD, like the C6, is a one-piece casting that includes bellhousing and main case, which makes the AOD different from the C3, C4, and FMX transmissions with separate bolt-on bellhousings. Instead of a conventional rotary backup light/neutral safety switch at the manual shift linkage as seen with older Ford automatics, the AOD has a screw-in multi-pin linear connector backup light/neutral safety switch on the left-hand side above the manual shift and TV cable linkage.

The AOD has a filter retained with three fine-thread bolts and a 10-mm socket. The filter should never be cleaned and returned to service. Always replace it during a fluid change.

This is the AOD manual shift mechanism (left) and throttle valve linkage (right) with the valve body removed. The manual valve detent is a hollow shaft with the throttle valve shaft inside. Both have seals that should be replaced during a rebuild. This application has a Lokar aftermarket external linkage for column shift.

With the AOD valve body removed, two servo pistons and an accumulator are visible. From left to right are the overdrive band servo, low-reverse servo, and the 3-4 shift accumulator. The 3-4 shift accumulator was dropped in 1989 with the addition of a revised valve body and plate. If you use a 1980–1988 AOD valve body, you must have the 3-4 shift accumulator.

Ready to get your hands dirty rebuilding or modifying your Ford AOD transmission? Pick up this workshop book and get to work!

Here is the AOD main case with the servo/ accumulator covers and pistons removed. Ultimately, Ford eliminated the accumulator in production, which is why some AOD cores are not so equipped. The 3-4 shift accumulator was phased out in the 1989 model year due to leak issues. The valve body is also different to accommodate this production change; it employs a revised separator plate. If your AOD doesn’t have a 3-4 shift accumulator, don’t worry about installing one.

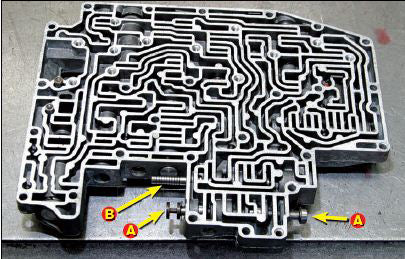

The AOD valve body mates with the main transmission case and is fitted with a manual shift valve (A) and a shift modulation throttle valve (B). The manual shift valve has been offered two basic ways: with an internal detent and with an external bolt-on roller detent. The throttle valve, which varies control pressure based on throttle position, depends on TV cable adjustment. With optimum cable tension, upshifts occur exactly when they’re supposed to, in synch with throttle position. Not enough tension and upshifts come too early. Too much tension and upshifts come late.

This AOD with a column shift shows the Lokar manual shift bell crank and TV cable installed in a vintage F-Series truck with FE big-block power. If you have a column shift, the manual shifter at the transmission points downward at 6 o’clock. Here, the Lokar TV cable (left) is disconnected.

A big improvement in efficiency with the AOD is the use of Torrington (needle) bearings throughout to reduce internal friction. Although there are some thrust washers in the AOD geartrain, friction is greatly reduced.

The real beauty of the AOD transmission is its easy fitment into just about any Ford application. Thanks to the perseverance of the aftermarket, such as California Pony Cars, it has become easy to swap the AOD into a vintage Ford, Mercury, or Lincoln with a variety of installation kits, which makes the AOD an excellent choice for any classic car project. If you already have an AOD in your late-model Ford, you understand this transmission’s benefits in terms of smooth operation and improved fuel efficiency. Key to getting along with the AOD is learning as much as possible about its function and how to properly execute a successful rebuild and tune.

Aside from the benefit of over-drive in the AOD, the other benefit is direct drive from the torque converter shell to the overdrive unit. What makes this different from most automatic overdrives is where lockup takes place: inside the overdrive unit instead of the torque converter via an inner input shaft. This feature offers non-slip direct drive in fourth gear (overdrive) and to some degree in third gear as well.

Do a gentle throttle tip-in and get both slippage and torque multiplication in third and fourth gears. Relax the throttle to get overdrive lockup and fuel-efficient direct drive between torque converter shell and output shaft. This is known as “split-torque.” It occurs when the transmission comes out of overdrive lockup during throttle tip-in for mild acceleration where you are on the torque converter getting torque multiplication. With torque multiplication, you get 2 to 21⁄2 times your engine’s torque.

The split-torque feature enables greater efficiency with torque multiplication as needed with throttle tip-in and straight drive with no slip-page at cruise. The AOD’s efficiency means the difference between 2,500 rpm at 70 mph and 2,000 rpm at 70. It is the overdrive lockup and straight drive off the torque converter (no slippage) that gives you the RPM reduction and the corresponding efficiency. It also makes the difference between 15 and 20 mpg. In addition, there is the benefit of less wear and tear with lower cruise RPM.

AODE/4R70W

To improve durability and make engine and transmission function more cohesive, Ford introduced the AODE in 1991. AODE, or AOD Electronic Control, delivers precision operation thanks to more unified engine and transmission electronic control. No TV cable adjustment, just predictable computer-controlled operation based on factory calibration, vehicle speed, and throttle position. The AODE was originally conceived for a new generation of overhead-cam Modular V-8s that first arrived in the 1991 Lincoln Town Car. The AODE was also installed behind the 5.0L and 5.8L Ford pushrod V-8s beginning in 1991. The AODE’s gearing gave these pushrod small-blocks extra snap under acceleration.

Although the AODE is similar to the AOD, there are important differences to be aware of before attempting a rebuild. The AODE really is a different transmission entirely even though it shares similar architecture. It has a different main case, valve body, torque converter, front pump assembly, input shaft, and other vital components. To improve shift quality, Ford eliminated the split-torque function in third and fourth gears.

Like the AOD (and FMX), the AODE has a Ravigneaux compound planetary gearset employing two sun gears and a dual pinion set offering four forward gears and one reverse. Also like the AOD, there are two bands, two one-way clutches, and four friction clutches to get the job done.

The AODE name was used from 1991 to 1992. The 4R70W (basically an AODE) was introduced in 1993 behind the 4.6L dual overhead cam (DOHC) V-8 only in the new Lincoln Mark VIII. It also appeared in some F-Series trucks that same year.

The AODE (electronically controlled AOD) arrived in 1991 to merge engine and transmission function for better performance and fuel economy. The AODE and 4R70W transmissions were an all-new AOD case designed for electronic interaction with engine controls.

The AODE and 4R70W are essentially the same AOD-based transmission. This is a 1997 4R70W with a speedometer drive and output shaft speed sensor. Visible here is the manual shift lever for a column shift. Missing is the backup light/neutral safety switch at the manual shift shaft.

This is the backup light/neutral safety switch on a 4R70W transmission. Just above this switch is the output shaft speed sensor. It works hand in hand with the PCM to unify engine and transmission cohesiveness.

The output-shaft speed sensor and plug are located on the driver’s side of an AODE/4R70W. The multiplex plug to the left is for the backup light/neutral safety switch on the driver’s side of the transmission.

On the AODE/4R70W’s passenger’s side is the shift solenoid and converter lockup multiplex plug that ties the transmission to the PCM. This connection eliminates the need for a TV cable and mechanical shift modulation.

This is the electronic speedometer drive sensor that takes the place of a cable drive and (phased-out) mechanical speedometer. However, the AODE/4R70W output shaft housing still accommodates a mechanical speedometer drive.

Start modifying or rebuilding your 4R70W transmission with this thorough guide!

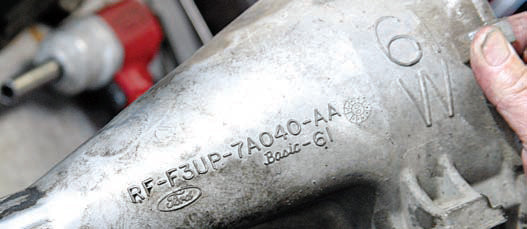

This is the tailshaft housing for an AODE or 4R70W with casting number RF-F3UP-7A040-AA and cavity number 61. This particular cast-aluminum tailshaft housing was produced by The Basic Aluminum Casting Company in Cleveland, Ohio, for the Ford Motor Company. The sand casting it came from was cavity 61, meaning there were at least 61 molds.

The AODE and 4R70W have a larger input shaft that connects a locking torque converter to the overdrive unit. The AODE/4R70W is different because there is one input shaft instead of both a primary and intermediate shaft.

The AODE/4R70W manual shift mechanism is basically the same as the AOD except it has no linear backup light/neutral safety switch. Instead, this function is outside the case. This is the pressure control solenoid, which is a large, heavy electro-magnet that pulses to control system pressure. If it malfunctions, you may experience severe transmission damage.

The AODE/4R70W valve body is different from, and not interchangeable with, the AOD. It lacks the throttle valve of the AOD. The system pressure programming and shift-points are computer controlled instead of being mechanically modulated. The manual shifter valve has a bolt-on detent to lock shift positions.

The AODE originally had a raw wiring harness that connected the multiplex system plug to the shift control solenoids and converter lockup solenoid. The 4R70W has a clever wire channel (A) that anchors into place with good security. The two side-by-side solenoids (B) are shift-control solenoids. The one lone solenoid (C) is for converter lockup in overdrive. At the far right near the shifter is the pressure control solenoid connection (D).

The AODE and 4R70W have a press-in filter requiring no tools for removal and installation. Take extra care to ensure the rubber seal and filter are secure before buttoning up. Remember, never reuse a filter.

Ford casting numbers can be found on all AODE, 4R70W, and 4R75 castings. These numbers are key to knowing which transmission you have and what parts should be used.

The AODE/4R70W transmission pan is unique to these electronically controlled units because it employs a different bolt pattern and a deeper sump for improved cooling and lubrication.

This is the AODE/4R70W planetary gearset, which uses an improved first-gear ratio for better acceleration. The AODE/4R70W gearset swaps into an AOD to get that better 2.84:1 to 1.55:1 1-2 upshift and holeshot.

The AODE/4R70W front pump is a totally new gerotor aluminum design that delivers the same pressures as the AOD iron gear pump, but at a greater volume at low engine speeds.

The AODE/4R70W multiplex plug connection enables the electronically controlled AOD to work seamlessly with engine operation. Instead of a TV cable that can move out of adjustment, it uses electronics for precision function.

The updated 4R75W and 4R75E have two shaft sensors for input and output shafts for greater cohesiveness between the engine and transmission. The 4R75-series transmission has a different main case to accommodate both sensors.

Another important change from the AOD is the use of a locking torque converter on the AODE and 4R70W instead of the split-torque overdrive unit lockup feature. Ford’s explanation for moving away from split torque was to create a more cohesive engine and driveline pack-age. With the AODE/4R70W, throttle tip-in while you’re in overdrive disengages the converter clutch, which enables torque multiplication with improved acceleration without having to switch from one input shaft to another. With the AODE and 4R70W it all happens via one input shaft. With the AODE and 4R70W, you have converter clutch engagement and disengagement instead of over-drive lockup.

The AODE front pump, made of aluminum with a steel rotor, is also improved for better flow at idle and increased lubrication and pressure. AOD and AODE front pump rotors differ in the number of rotor teeth and can be identified as such. The AODE/4R70W front pump is about volume and lots of it. The downside to the aluminum pump is somewhat reduced durability.

The AODE/4R70W also uses a new-and-improved valve body with two computer-controlled solenoid packages consisting of two shift solenoids and one converter clutch solenoid. According to Ford, the AODE valve body is thicker for improved strength and durability. Valves in the AODE are made of aluminum instead of steel for decreased weight and improved sealing because both valve body and valves have the same expansion properties.

What makes the 4R70W different from the AODE is lower gear ratios in first and second gears, which improve acceleration. The 4.6L Modular V-8 engine needs this feature more than the 5.0L and 5.8L pushrod V-8s because the 4.6L doesn’t have the same torque curve as a small-block. Lowering the AODE’s first-gear ratio helped improve standing-start takeoffs with the Modular V-8 engine.

4R75W and 4R75E

The 4R70W has evolved to be an even better transmission with engineering refinements leading to the 4R75W and 4R75E, introduced in 2003, which employ even better computer control thanks to the use of input and output shaft sensors.

Most of the improvements have to do with shift control via the valve body. Torque capacity became better along with gearset durability improvements and a more durable overdrive drum. The 4R75’s ring gear has 24 tabs instead of 6 for the output shaft sensor for more precise shift control.

With the 4R75W and 4R75E came an improved front pump and torque converter, as well as the input shaft sensor already mentioned. There’s also a refined vehicle speed sensor to fine-tune performance as you drive. Another important development with the 4R75W and 4R75E is additional programming in the powertrain control module (PCM), or computer, that enables use in drive-by-wire vehicles.

Written by George Reid and Posted with Permission of CarTechBooks