LS Engine Swaps: Transmission and Clutch Guide

Adaptability is the name of the game for a Gen III/IV LS engine. No matter the kind of vehicle you have in mind, an LS and your favorite transmission can swap into it. Or you can start a few steps earlier and build the engine before swapping it into a Camaro, Firebird, Chevelle, GM A-body, or bolt it to anything from a 2-speed Powerglide to a 4L80E. The Gen III/IV is compatible with automatic and manual transmissions–stock or modified. The following is an excerpted LS transmission swap guide that gives plenty of examples on how to get a Gen III/IV into almost any vehicle.

Find more tips in the book: LS SWAPS: HOW TO SWAP GM LS ENGINES INTO ALMOST ANYTHING

Get your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy and paste this link to share: https://www.cartechbooks.com/blogs/techtips/ls-swaps-transmission-and-clutch-guide

Automatic Transmissions

Bolting an older transmission to an LS engine requires specialized spacers and flexplates because the Gen III/IV engines are shorter. If you simply bolt an old-style converter to an LS engine without a spacer, you will have major problems after only a few miles of driving. The pump seal will be ruined and will start to leak, causing the pump to fail. The converter doesn’t fit and will not center on the back of the crank. To make up for the difference, special conversion flexplates are required.

The GM 4L60-E is the most popular and most common automatic transmission coupled to a Gen III/IV engine because it efficiently transmits power to the driveline, it’s strong, and it’s reliable. The overdrive is electronically controlled for precise performance. An evolution of the popular 700R4, the 4L60E, is a popular swap transmission. (Photo Courtesy General Motors)

Flexplate

The 6.0-liter Vortec with a 4l80E transmission is the only Gen III/ IV engine that accepts an early GM transmission without a flexplate adapter or spacer. These vehicles came with the GM spacer and bolts and the flat factory flexplate. These are basically the same components needed for the older transmission swap, just performed at the factory.

General Motors offers the spacer plate and longer bolts over-the-counter. TCI has conversion flexplates for automatic transmissions and kits that include the spacer and longer bolts. You must use a crankshaft spacer, such as the Hughes Performance, TCI, or GM spacer and bolts, or a custom converter must be made with a longer-crank hub. The Bowtie Overdrives LS swap torque converter eliminates the need to use a spacer; it bolts directly to the stock flexplate. If you’re installing a used engine, the best solution for the transmission fit issues is to use the transmission that came with the engine. Then all you have to do is fit the transmission to the car.

If you are going to run any automatic transmission other than the correct late-model automatic, you need an adapter ring like this one from General Motors. It adds the required space so the nose of the torque converter fits with the crank. (Photo Courtesy Street & Performance)

The flexplate on the right is the adapter plate, which allows an early-style torque converter to bolt up. The unit on the left is the stock unit. Note the dish on the stock flexplate; this is another reason you must use an adapter flexplate for older transmissions. (Photo Courtesy Street & Performance)

This flexplate adapter from TCI allows you to use an older GM automatic transmission with a Gen III/IV LS-engine and it’s also SFI-certified for racing. (Photo Courtesy TCI)

Here, the dish is in the center of the stock flexplate. Because the flexplate is not flat like previous GM units, a special adapter is required when combining the LS with older GM transmissions. (Photo Courtesy Street &Performance)

Flywheels are more than just a connector between the transmission and the engine; they are an integral component to the clutch. The flywheel can also affect the driving characteristics of the engine. A heavy flywheel holds more inertia for smoother shifts and easier street driving. A lighter flywheel allows for quicker revs and shifts; they are great for road racing. This is a RAM 19.2-pound LS7 flywheel bolted to an LS3. (Photo Courtesy Blane Burnett)

The clutch mounts between the flywheel and pressure plate. This is a single-disc LS7 system. If you require more power, twin-disc clutch kits are available for the LS-series engine. (Photo Courtesy Blane Burnett)

TV Cable

Adapting the non-electronically controlled 700-R4 and 200-4R requires a little more work. The most important component of these two overdrive transmissions is the throttle-valve cable, or TV cable. This crucial system tells the transmission when to shift and determines the amount of pressure sent to the clutches. If this cable is off by even the slightest amount, the clutches do not fully engage, causing the transmission to burn up and eventually fail. Adapting the TV cable to the throttle body on an LS engine is challenging, and you need to maintain the right geometry. Doing this requires in-depth knowledge of the TV cable system, and is not suggested for novices. Aftermarket manufacturers, such as Bowtie Overdrives, offer bolt-on solutions for conversion from TV cable to throttle body.

It looks a little odd compared to the earlier Gen I engines, but General Motors left off one of the boltholes on the back of the block. Other than looks, there is no difference in the bolt pattern. Any older GM bellhousing bolts up. (Photo Courtesy Street & Performance)

On older overdrive transmissions, such as this 200-4R, the TV cable is a crucial component. If it is not set right, the transmission may burn out within a few miles, so take the time to ensure it’s properly adjusted.

Computer Controls

Almost all Gen III/IV engines in salvage yards, at swap meets, and on Internet sites already have a transmission attached, and the transmission is generally an automatic. The most common GM automatic is the 4L60E or the 4L65E variant (they are the same dimensionally, but the -65 version has an extra pinion gear internally), depending on whether the engine came from a car or a truck. The larger Vortec engines were typically mated to the 4L80E (and 4L85E variant) automatic transmission. These transmissions require computer controls that are contained in the factory ECM. However, these transmissions can be purchased separately through the aftermarket for carbureted LS conversions or when an aftermarket electronic fuel injection (EFI) controller is used.

Mechanical/electronic adapters bolt onto the transmission and feed the electronic signal to the computer. A cable then connects to the other side. These are available from Street & Performance, AutoMeter, and most gauge suppliers. (Photo Courtesy Street & Performance)

These units from Dakota Digital help convert the transmission’s VSS signal to non-programmable electronic speedometers if yours is not compatible with the stock VSS signal. (Photo Courtesy Street & Performance)

If the radiator does not have a built-in transmission cooler, it’s necessary to add an external cooler when running an automatic. This unit from TCI keeps just about any GM high-performance transmission cool. It is placed in front of the radiator.

For the newer transmissions, you need to adapt the speedometer output to mechanical output in order to use a mechanical speedometer. These mechanical speedometer tailshafts are for the 4L60E and 4L65E transmissions. (Photo Courtesy Street & Performance)

The tailshaft gear drives the speedometer gear, which in turn, drives the speedometer cable to the speedometer. Adapters are available for electronic speedometers, as well as different gears for tuning mechanical speedometers. (Photo Courtesy Street & Performance)

This tailshaft is for the 4L80E transmission commonly found in larger trucks. The 4L80E can handle a lot of torque; it is quickly becoming the go-to automatic for high-performance LS swaps. (Photo Courtesy Street & Performance)

In 2006, General Motors released a couple of 6-speed automatics for their vehicles. The 6L80 and 6L90 transmissions are used in heavy-duty GM trucks and most of the performance cars. The Sigma platform, which covers the Cadillac CTS line, uses either the 5L40/5L50 5-speed or the 6L45/6L50 6-speed automatics.

Custom Swaps

The aftermarket has a vast number of custom-application GM transmissions that work great for LS swaps. One in particular is the TCI 6X 6-speed automatic. It is based on the 4L80E but with new guts to provide six forward gears capable of handling 850 hp. These can be configured in several ways and come with a TCI transmission controller. They can even be set up for a paddle shifter.

The Tremec T-56 6-speed manual is the most popular transmission for LS swaps. It bolts right up and requires only slight trimming or denting of the transmission tunnel to fit most GM cars and trucks. (Photo Courtesy Street & Performance)

T56 Manual Transmission

The 6-speed T56 manual is the most popular transmission used in LS engine swaps. Formerly offered on the 1998–2002 F-Body and GTO, the T56 bellhousing, flywheel, and clutch pack are readily available. The T56 transmission fits into most GM muscle cars, requiring only minor modifications, if any, to the transmission tunnel. Swap kits help make the install easier. Classic Motorsports Group offers a kit for first-generation Camaros, Firebirds, and Novas

The 1968–1974 Nova requires that the transmission tunnel be enlarged. The clutch mechanism, however, definitely requires some modifications. There are several ways to get around the clutch mechanism, such as using an older-style manual clutch or a modern hydraulic clutch. As a side note, the 1993–1997 T56s use an external clutch slave cylinder, while the later 1998-up units use an internal slave cylinder. The 1998-up T56 transmission is better suited for the Gen III/IV engines with the correct bolt pattern and input shaft, but McLeod offers components that adapt older T56 transmissions to the Gen III/IV engines.

Find more tips in the book: LS SWAPS: HOW TO SWAP GM LS ENGINES INTO ALMOST ANYTHING

Get your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy and paste this link to share: https://www.cartechbooks.com/blogs/techtips/ls-swaps-transmission-and-clutch-guide

Mounting Plate

Street & Performance offers a few components that assist in adapting the hydraulic clutch to most GM vehicles, and they can be modified to work with other vehicles as well. The first component is the slave cylinder mounting plate. Available in two versions, 1958–1964 and 1967-up, this plate mounts between the vacuum booster (or master cylinder) and the firewall. The mount holds the master cylinder (GM PN 12570277) to the hydraulic clutch. The clutch fluid reservoir is mounted on the firewall.

Clutch Pedal Adapter Tab

To bolt the original clutch pedal to the master cylinder pushrod, an adapter tab must be installed on the original pedal. This tab must be fabricated and welded to the clutch pedal. The placement of this tab is absolutely critical. If the tab is too high, the pushrod does not fully engage. If it is placed too low, the pedal is hard to push.

Using a piece of 3/16-inch-thick mild plate steel cut to 1 x 31⁄18 inches, the tab should be bent into a Zshape, .300 inch wide, starting at the 1.712-inch mark. Once bent, the tab is drilled with a 3/8-inch hole, measured from the long side of the tab at 2.629 inches on center. The placement of the tab on the pedal is 1.769 inches from the center of the square hole at the top of the pedal, and it sits at 114 degrees from the pedal side to the top of the tab.

Adapter brackets are available for mounting the hydraulic clutch unit to the firewall based on the brake booster mounts. Brackets are available from Street & Performance (shown), Detroit Speed & Engineering, and several others; or you can make your own. (Photo Courtesy Street & Performance)

Late-model transmissions and LS engines do not make installing a mechanical clutch simple. Although it can be done, it may not be worth the effort. A hydraulic throw-out bearing setup is the simplest solution. (Photo Courtesy Blane Burnett)

The plate bolts in directly behind the brake booster, then the clutch master cylinder bolts on. This is a finished installation. The second line coming off the master cylinder leads to the remote-mount fluid reservoir. (Photo Courtesy Street & Performance)

Adapting the hydraulic clutch requires some modification of the stock clutch pedal. This diagram works for all GM muscle cars and early F-Bodies, but double-check your particular application before welding anything. (Illustration Courtesy Street & Performance)

Here is the tab in place just before welding it on. It must be correctly positioned. Remember, this is only necessary when using a hydraulic clutch. (Photo Courtesy Street & Performance)

Shifters are interchangeable as long as you swap the receiver (the part that the shifter lever ball operates) bolted inside the transmission. It is retained by a roll pin. (Photo Courtesy Street & Performance)

If the car did not have a manual transmission before, cut the hole in the ideal location, similar to this 1969 Camaro. (Photo Courtesy Street & Performance)

If your car has a manual transmission and you want to retain the stock console, you need an adjustable shifter, such as this one from Driveline Components Company. This shifter allows for clearance of some floorpans, where a stock-style shifter doesn’t. (Photo Courtesy Street & Performance)

The tab should then be fully welded to the pedal arm. The small, triangular-shaped section of the tab that overhangs the pedal on the underside is trimmed off. The clutch pushrod bolts to the tab via a 3/8-inch bolt and locknut. It is possible to adapt the LS engine to use a manual clutch linkage. If you are installing an LS and manual transmission in a GM vehicle originally available with a manual clutch setup, you need linkage, clutch, Z-bar, and related components. The Gen III/IV blocks are not drilled for the Z-bar, which makes it difficult to adapt the LS engine to a manual linkage. Fabricating a simple bracket that locates using the bellhousing bolts and attaches to the Z-bar is the best solution.

Find more tips in the book: LS SWAPS: HOW TO SWAP GM LS ENGINES INTO ALMOST ANYTHING

Get your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy and paste this link to share: https://www.cartechbooks.com/blogs/techtips/ls-swaps-transmission-and-clutch-guide

Shifter

The T56 uses a top-mounted shifter at the rear of the transmission, which creates a compatibility issue for the stock console or shifter location in GM vehicles. This is easily rectified using the Street & Performance shifter relocator kit. As engine and transmission mounts differ, each shifter must be ordered individually.

The T56 relocator shifter can move the shifter 1 to 4.1 inches forward. In addition, the shifter can be centered or offset to the left or right. If you choose to use the stock T56 shifter, it is placed approximately 4 to 5 inches rearward from the stock location, 1 to 2 inches rearward for 1970–1974 F-Bodies, and 4 to 5 inches rearward in the 1968–1974 Nova.

Here is a GTO shifter (left) and a new Hurst F-Body-style shifter (right). The placement of the handle is critical. The Hurst shifter is more accurate through precision machining. (Photo Courtesy Blane Burnett)

Tremec TKO Manual Transmission

Another popular manual swap is the Tremec TKO 500 or TKO 600. These 5-speed manual transmissions are very popular among GM muscle builders and offer excellent performance. Classic Motorsports Group offers complete kits for installing the TKO into almost any GM muscle car and 1960–1972 Chevy trucks. These kits feature hydraulic clutches, bellhousing, and all the components to make the installation simple and easy.

TKO transmissions use a top-mounted shifter. To adapt these shifters to match the stock location, a Hurst Blackjack shifter can reposition the shifter to the ideal location.

The TKO transmission does not fit quite as neatly under the body as the T56 does. This transmission fits some GM vehicles without modifications, while others require serious cutting. The Tri-Five Chevy and similar-era GM cars, 1967–1981 F-Body (Camaro and Firebird), and C1–C3 (1956–1981) Corvettes do not require any floorpan modifications. The C4 Corvettes fit the TKO, but the stock shifter box must be removed and patched.

The 1964–1972 GM A-Body (Chevy Chevelle, Buick GS, Olds 442, etc.), 1960–1969 B-Body (Impala), and 1962 Novas all require a large section of the transmission tunnel to be removed and replaced with a reshaped panel. The Classic Motorsports kits come with the requisite patch panel, cut guide, and instructions, taking the guesswork out of the swap.

For reasons that may include nostalgia, economy, personal taste, simplicity, or originality, some builders prefer to keep the stock manual gearbox in their muscle car or truck when swapping in a Gen III/IV engine. These swaps bolt up similarly to the automatic transmissions, but require a few specialized parts.

Bellhousing

The input shaft is too far from the crank with a stock bellhousing (the same situation as with the automatic transmission). There are two ways to remedy this problem. The first and best way is to use a retrofit bellhousing and flywheel package. General Motors sells these components individually through its Chevrolet Performance dealers.

The Chevrolet Performance retrofit bellhousing features thick-wall titanium and aluminum alloy construction; CNC machining, including spot-faced mounting holes; precision dowel pin holes; and bores that yield a precise fit. This bellhousing bolts to all GM Gen III/IV V-8 engines for the installation of the Muncie, T-10, Saginaw, Richmond, Tremec TKO, Tremec T56-011, and other specially built transmissions.

This bellhousing works with stock clutch linkage and hydraulic clutch actuators, and includes steel inspection cover and mounting hardware. It is also designed to use a 168-tooth flywheel and standard GM starter. This bellhousing is lightweight (15 pounds) and uses all factory linkage parts, including clutch forks, Z-bar, rubber dust boot, etc.

According to Chevrolet Performance, the LS Truck flywheel (PN 12561680), 12-inch clutch and pressure plate (PN RAM88744), and six metric pressure plate bolts (PN 12561465) must be used.

Aftermarket Kits

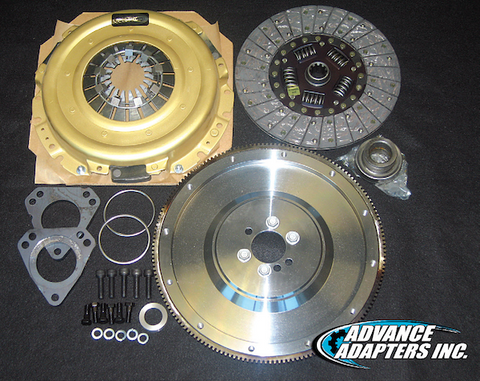

Clutch kits are available from aftermarket sources such as McLeod and Advance Adapters. They are designed to adapt the Gen III/IV engines to early-style GM manual transmissions, such as the M21/M22, SM420, SM465, and NV4500. Additionally, these kits allow the installation of Richmond Gear manual transmissions, such as the Richmond Overdrive 6-speed.

The Advance Adapters clutch kits typically include a custom flywheel, 11-mm flywheel bolts, 11-inch centerforce pressure plate and disc, pilot bushing spacer, throw-out bearing, collector gasket, 10-mm bellhousing bolts, 10-mm lock washers, and XRP dowel bolts. If you want to assemble your own parts, the key is to match the flywheel and clutch to the engine, while making sure the splines on the clutch disc match the transmission.

GM transmissions use 10- and 26-spline input shafts; early manuals (before 1971) typically have 10 splines, and later units have 26 splines. That being said, some other aftermarket manual transmissions have either 10 or 26 splines. A 26-spline shaft is more durable than a 10-spline shaft because it distributes the input load better.

This kit from Advance Adapters allows any older GM manual transmission to bolt up to a Gen III/IV engine. It includes the adapter flywheel, spacers, clutch, and everything else needed to make an older transmission, such as the M22, fit an LS engine. (Photo Courtesy Advance Adapters Inc.)

The T56 needs a different tailhousing for a mechanical speedometer. Most stock units have electronic sensors for electronic speedos. (Photo Courtesy Street & Performance)

As a side note, the Advance Adapters kit can be used with Gen III engines mounted to Jeep manual transmissions (PN AX15/NV3550) and Ford manual transmissions (PN NP435/T-18). The throw-out bearing retainer must be machined to accept the adapter bearing, and a different clutch disc is likely needed.

The other option is to use an extended bearing. This retains the original old-style bellhousing, matches the clutch to the engine, and uses a longer bearing to make up the difference for the shorter crank flange. There are several manufacturers of these bearings, including McLeod (PN 8617) and General Motors (PN 12557583). By using the old-style bellhousing, you should have a provision for the Z-bar and be able to run a manual clutch setup.

Written by Jefferson Bryant, author of LS Swaps: How to Swap GM LS Engines into Almost Anything

Find more tips in the book: LS SWAPS: HOW TO SWAP GM LS ENGINES INTO ALMOST ANYTHING

Get your copy here!

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in forums, or with any clubs you participate in. You can copy and paste this link to share: https://www.cartechbooks.com/blogs/techtips/ls-swaps-transmission-and-clutch-guide